Dear visitor! Our new website feature is currently in debugging mode, so we apologise in advance for any inconvenience. We would be grateful if you could share your experience with us at [email protected]. After all, we are working to make the system convenient for everyone.

The Printing Industry Still Runs on Chaos and Trust

Informal phone calls, unpaid ‘quick consultations’ and uncertain payments have become the norm

Free consultations became “normal” — and they devalue your expertise

No one expects a lawyer to work “for free.” Yet in printing, experts are often pushed into giving diagnostics, recommendations, and time without pay — just to keep the contact alive.

A service engineer comes on site, fixes the problem, saves production — and then spends weeks reminding the client to pay. It’s humiliating and turns service into stress instead of a profession.

You deliver the work or supply the parts — then you still have to beg to get paid

Paying upfront feels risky too — because real guarantees are missing

Printing companies are also reluctant to pay contractors in advance for services (e.g., dismantling) when they are unsure of the quality and timeliness of the service. In manufacturing, mistakes are costly.

Pressinspection successfully solves the problem of trust between parties

Enter all your goods, services and skills into the system and simply send your customer a link to your service.

See how we protect both sides.

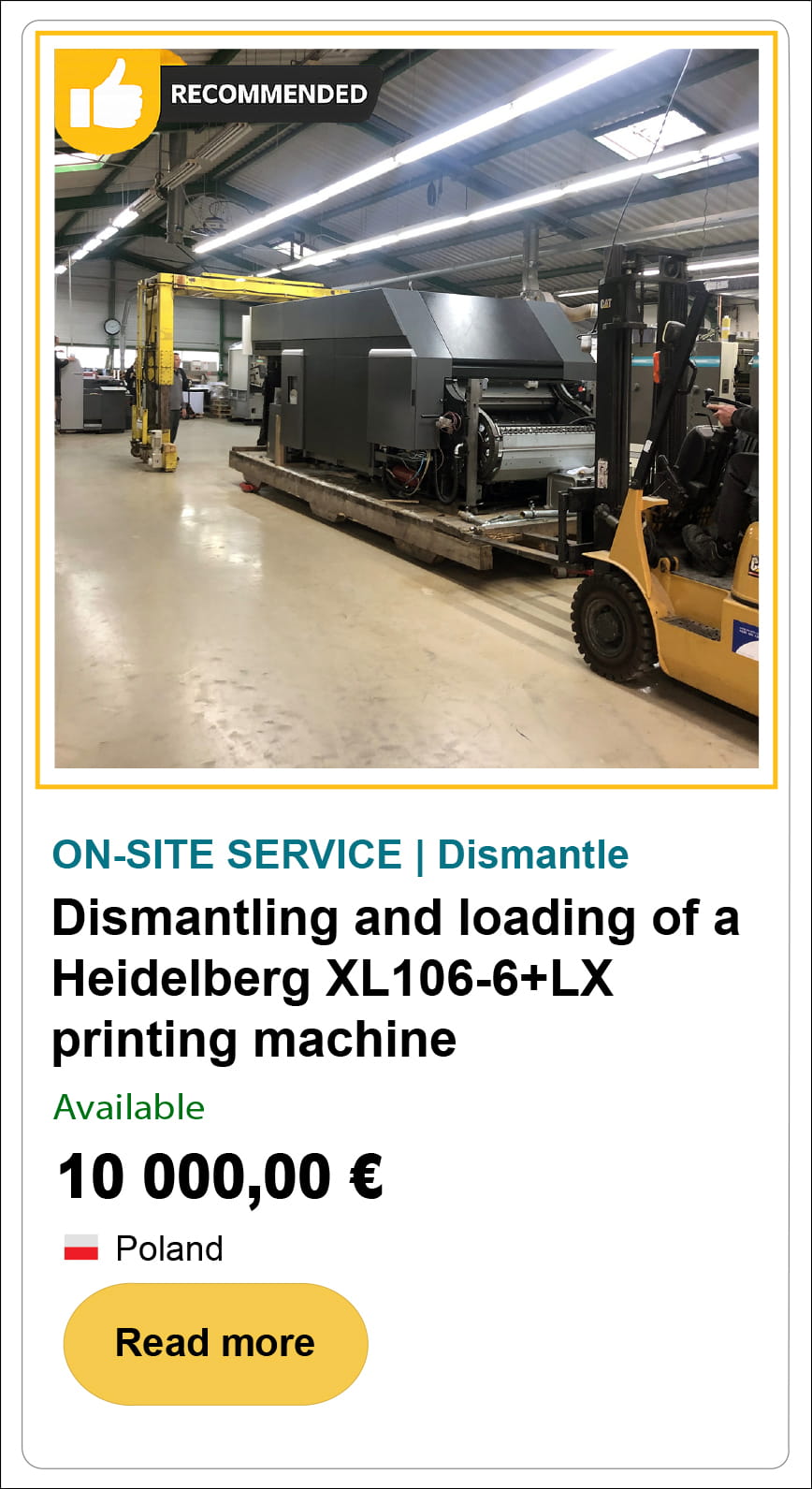

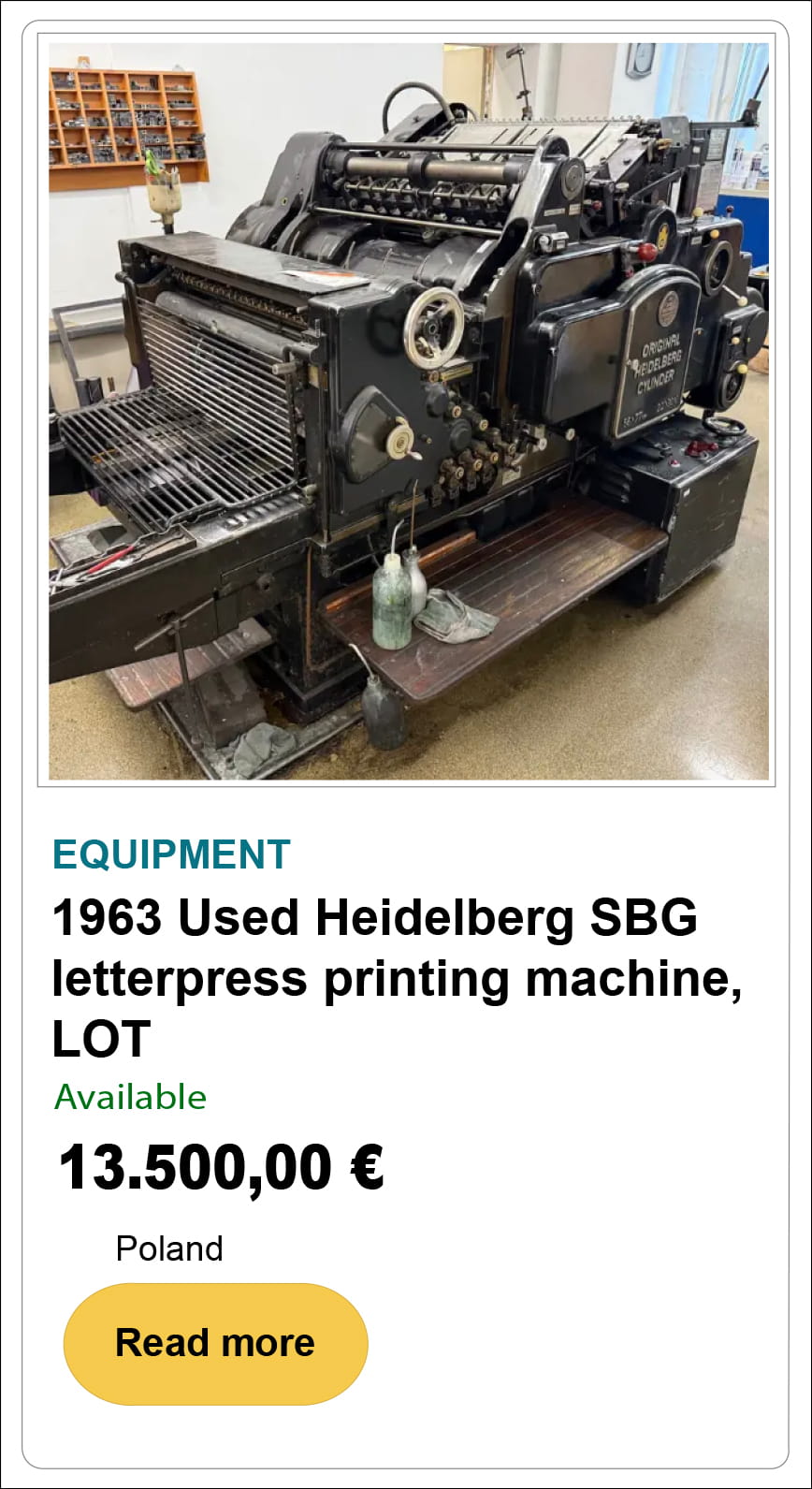

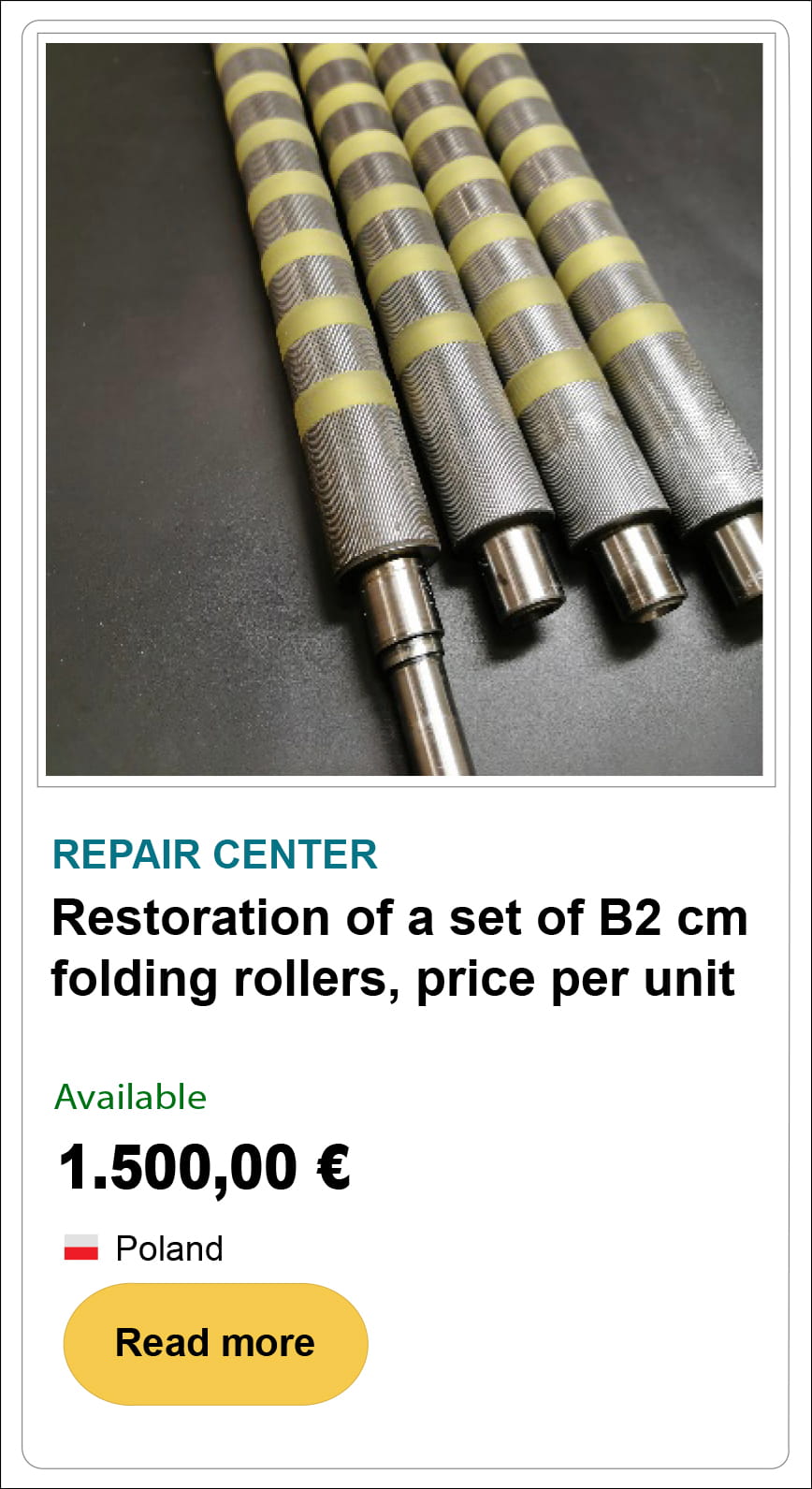

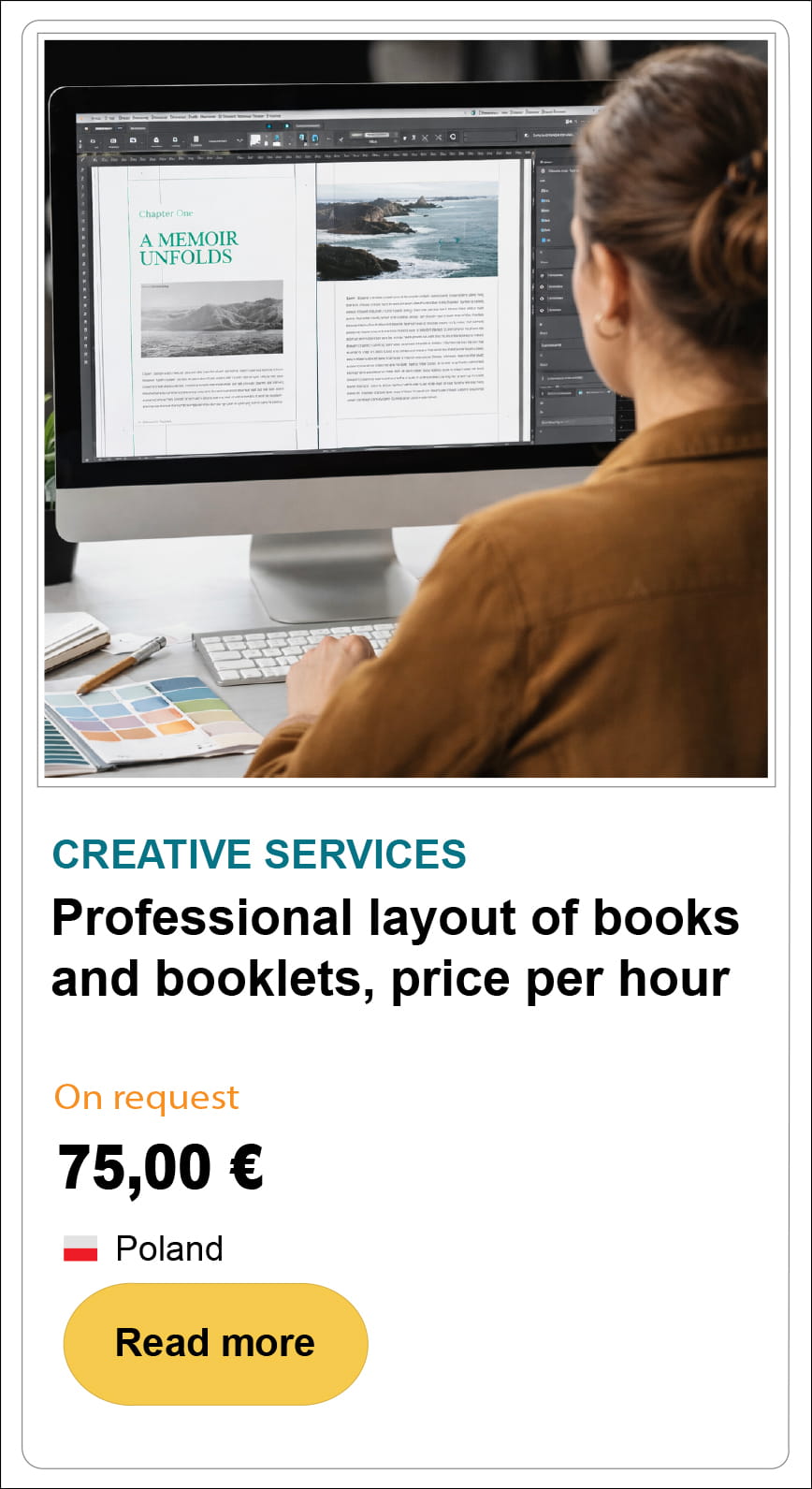

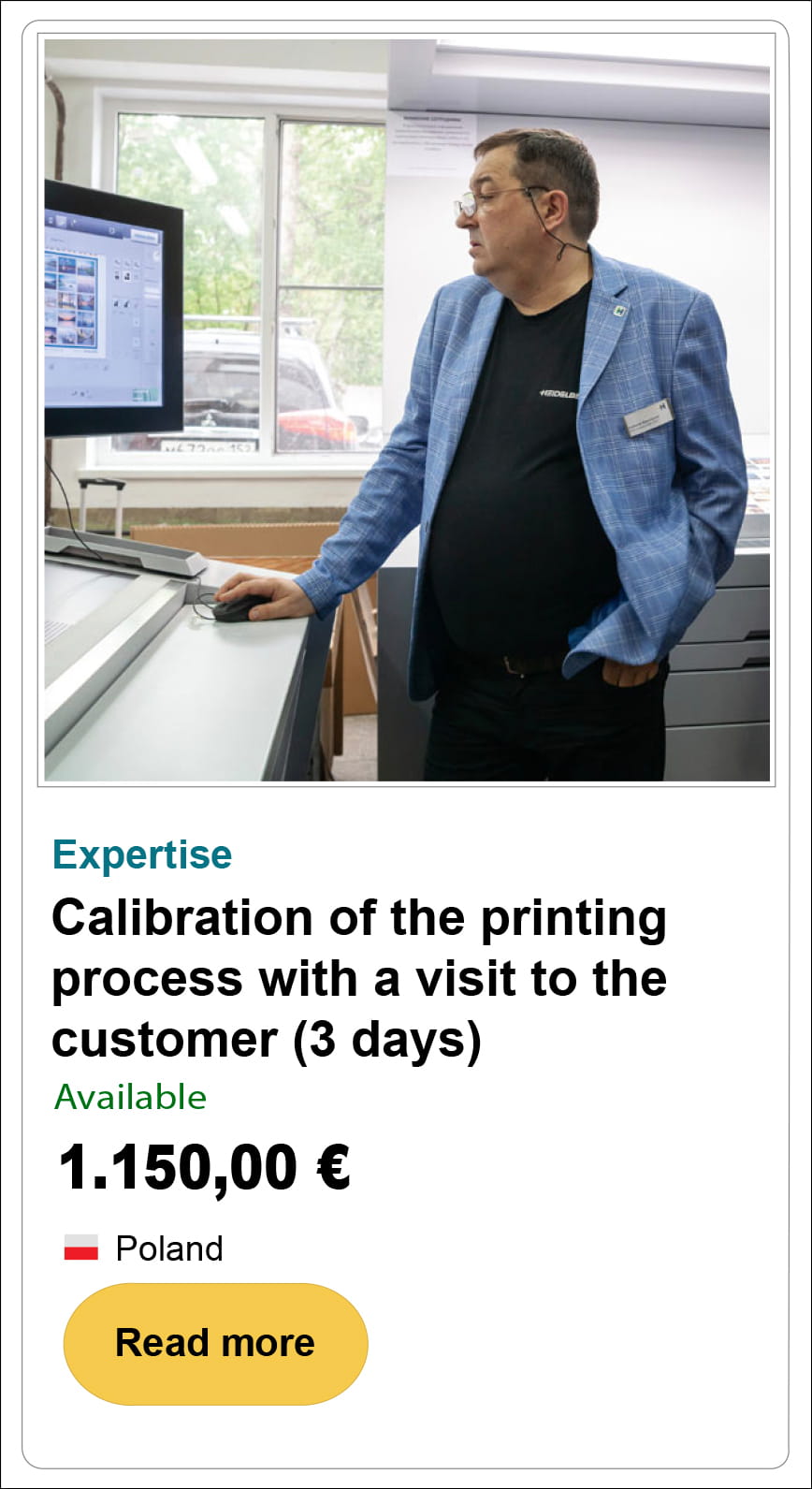

Organise your services into CARDS.

Make them visible to everyone!

Organise your services into CARDS.

Make them visible to everyone!

Organise your services into CARDS.

Make them visible to everyone!

Organise your services into CARDS.

Make them visible to everyone!

What Changes When Service Delivery Become a System

One professional environment instead of scattered contacts, calls, and emails

Printing Factories & Publishing Companies

Stop searching for solutions through personal contacts and endless calls.

Use a structured system to find the right service, the right expertise, and the right specialist — with clear terms and reduced risk.

Use a structured system to find the right service, the right expertise, and the right specialist — with clear terms and reduced risk.

Service Engineers & Professional Consultants

Replace chaos with structure.

Use one professional tool to organize requests, manage availability, handle bookings, and work within a transparent system designed for real service work.

Use one professional tool to organize requests, manage availability, handle bookings, and work within a transparent system designed for real service work.

Dealers, Manufacturers & Independent Specialists

Be visible where the industry actually works.

Join a professional environment built specifically for printing services — not social networks, not generic freelance platforms.

Join a professional environment built specifically for printing services — not social networks, not generic freelance platforms.

How the System Works in Practice

Our system guarantees the integrity of the transaction and prevents abuse by both the seller and the buyer

Choose the Service

Provision of Services and Sale of Goods

Find a clearly defined service by category, location, and expertise.

No vague promises, no guessing — you select based on transparent offers and real specialization, whether it’s an inspection, repair, relocation, troubleshooting, or consulting.

No vague promises, no guessing — you select based on transparent offers and real specialization, whether it’s an inspection, repair, relocation, troubleshooting, or consulting.

Send Payment Securely

Funds Are Held Until the Work Is Confirmed

The payment is secured and released only after completion and approval.

This removes the two biggest risks in production service work: prepayment without results and disputes without rules. Both sides operate inside one controlled process.

This removes the two biggest risks in production service work: prepayment without results and disputes without rules. Both sides operate inside one controlled process.

Secure payments powered by Stripe

Confirm the Result

Get Documentation and Accountability

You approve the outcome when the task is done, and the provider gets paid only then.

If the task is not fulfilled as agreed, the payment is returned. You get a clear record of the service — and the provider works in a professional environment, not through chaotic phone calls.

If the task is not fulfilled as agreed, the payment is returned. You get a clear record of the service — and the provider works in a professional environment, not through chaotic phone calls.

Secure payments powered by Stripe

Blog About Printing Presses

Insights for the Printing Industry

Expert tips, industry news, and technical guides for printers around the world.