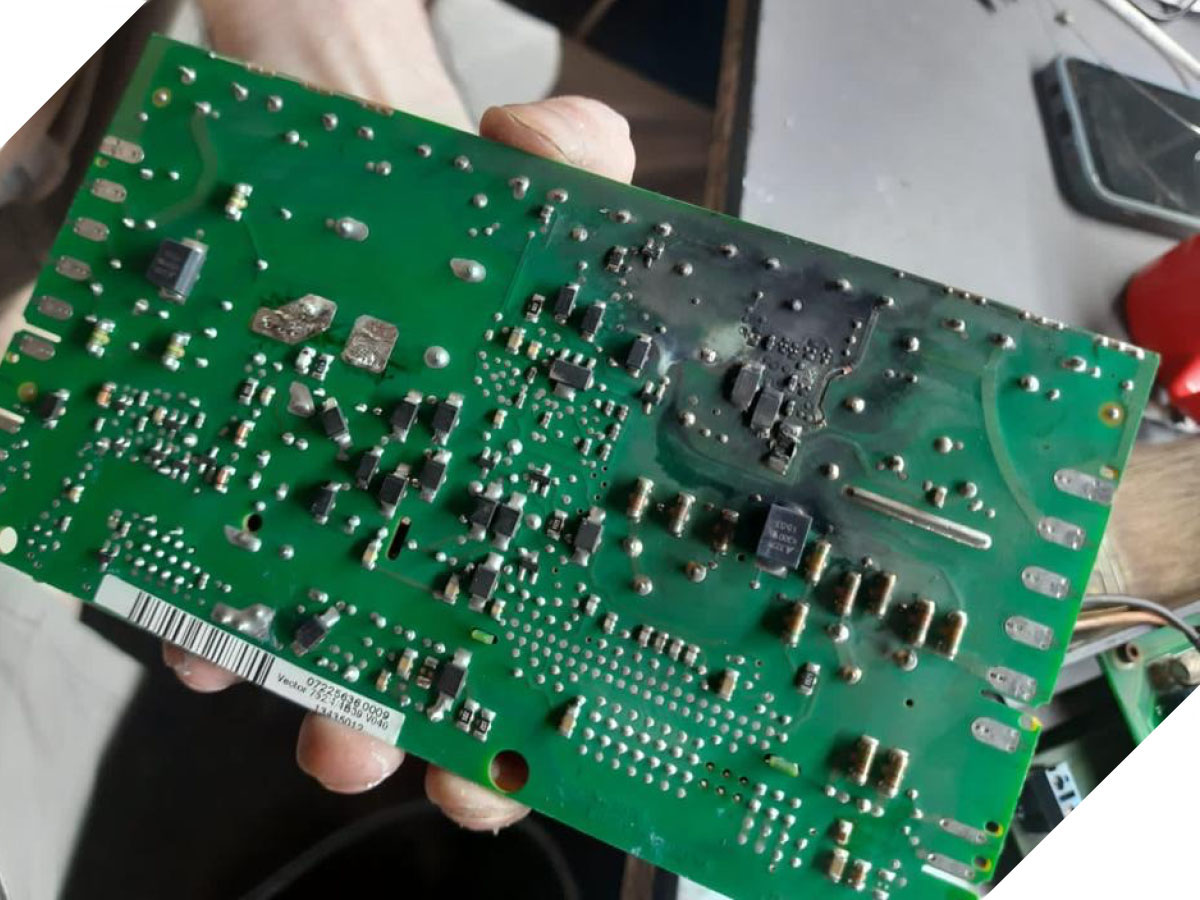

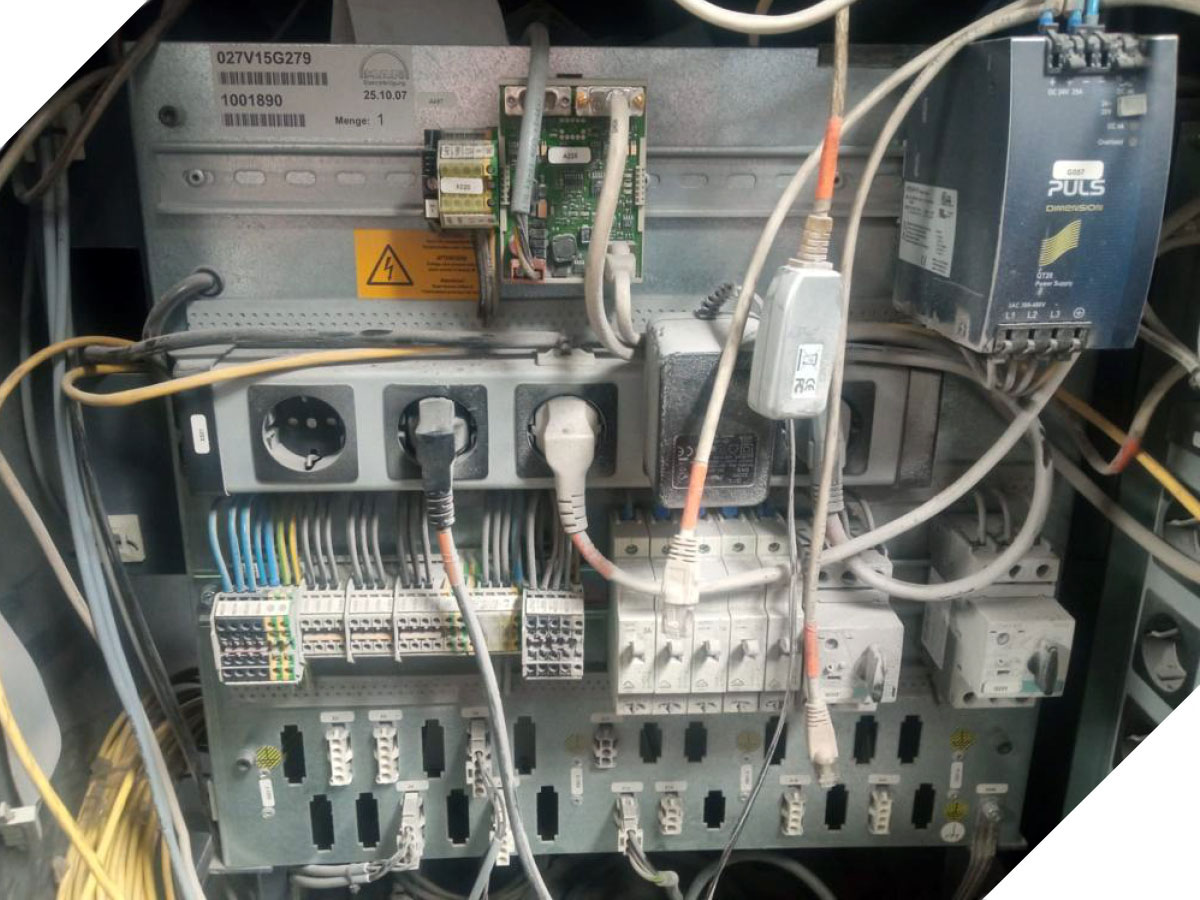

Imagine you want to buy any machine for printing industry and have already found a suitable offer from a dealer. However, you don’t know what has happened to the machine in the past and what is hiding inside behind the beautiful pictures. Look at the pictures we took these pictures in different locations over a period of several months. All these, and many other problems after payment become the buyer’s headache.

The seller will definitely show you what you want to see. However, when you pay the money and the machine arrives at your print shop, there may be many troubles you didn’t even realise were there. Cinderella’s beautiful carriage turns into an unmoving pumpkin, and now you’ll have to think about where to get the money for repairs.

Book our independent inspection of the used machine before you pay for it. Our inspection reduces the risk of costly repairs in the future.

Professional Inspection Оf Printing Machinery

You want to buy any machine for printing industry and have already found a suitable offer from a dealer. However, you don't know what has happened to the machine in the past and what is hiding inside behind the beautiful pictures. Look at the pictures we took these pictures in different locations over a period of several months. All these, and many other problems after payment become the buyer's headache.

The seller will definitely show you what you want to see. However, when you pay the money and the machine arrives at your print shop, there may be many troubles you didn't even realise were there. Cinderella's beautiful carriage turns into an unmoving pumpkin, and now you'll have to think about where to get the money for repairs.

Book our independent inspection of the used machine before you pay for it. Our inspection reduces the risk of costly repairs in the future.

Consider the consequences of your purchase BEFORE paying, not AFTER.

The reliability of a used printing machine depends not on the manufacturer, but on the owner's attitude towards it.

Collection of Defects in Used Printing Machines

Collection of Defects in Used Printing Machines

Absolute Benefits For Each Party Of The Deal

Example of an Inspection Certificate

Following the inspection, the customer will receive a certificate of inspection as well as a detailed report on each of the assemblies in PDF. Photos and videos will be available at the link.

In order to maintain confidentiality, the certificate is issued by machine model and serial number, without reference to the name of the printing house and the place of inspection. If the customer is a seller, he is free to pass the certificate to his potential buyer without disclosing the location of the machine.

The purchaser can request the authenticity of the issued certificate from us on the website. In doing so, we maintain the confidentiality of all parties.

PROTECT YOURSELFFor Buyers

SELL FOR MOREFor Sellers

SELL HONESTLYFor Dealers

EVALUATE ACCURATELYFor Lessors

How Much Is Your Confidence Worth?

- For any kind of equipment

- Three working days incl. arrival and return

- All expenses within the EU

- Detailed inspection of all quality-relevant components

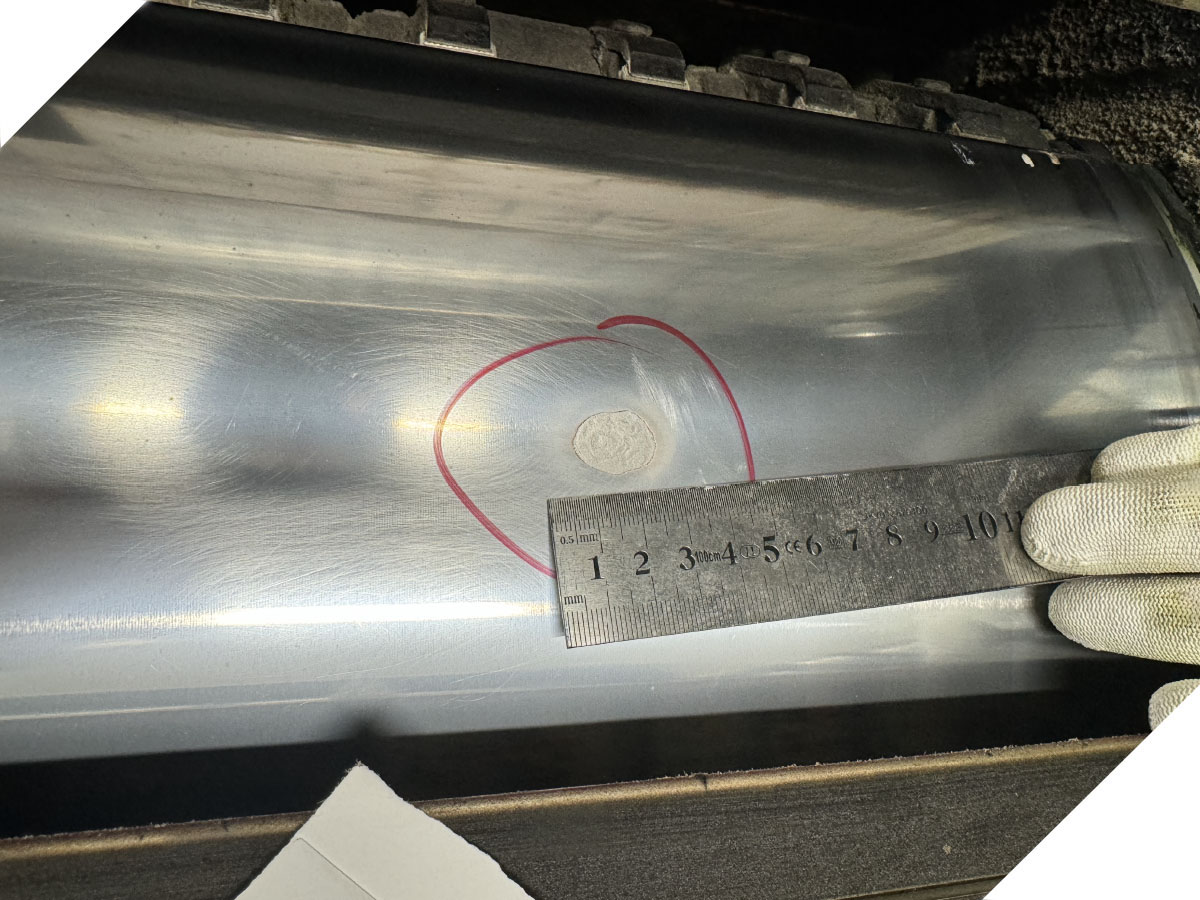

- Visual inspection of cylinder condition

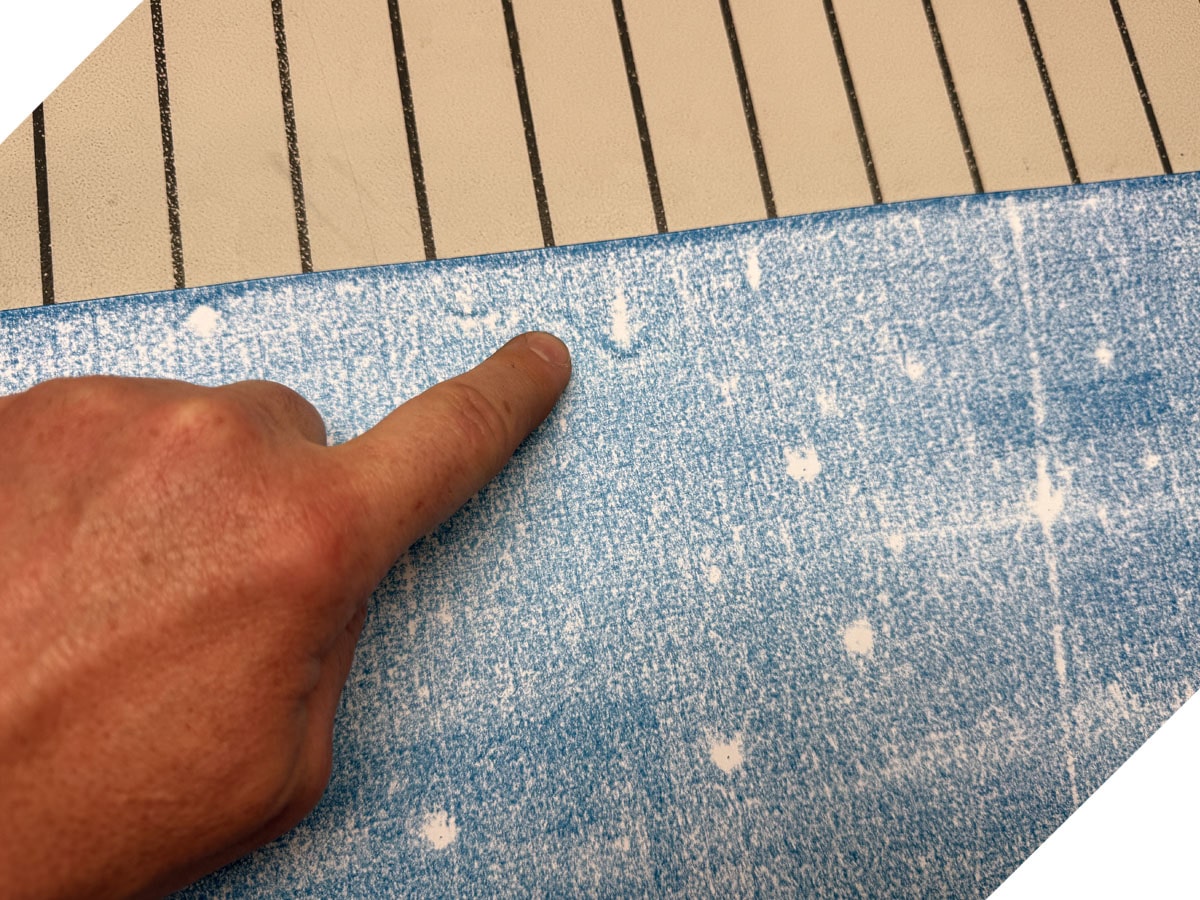

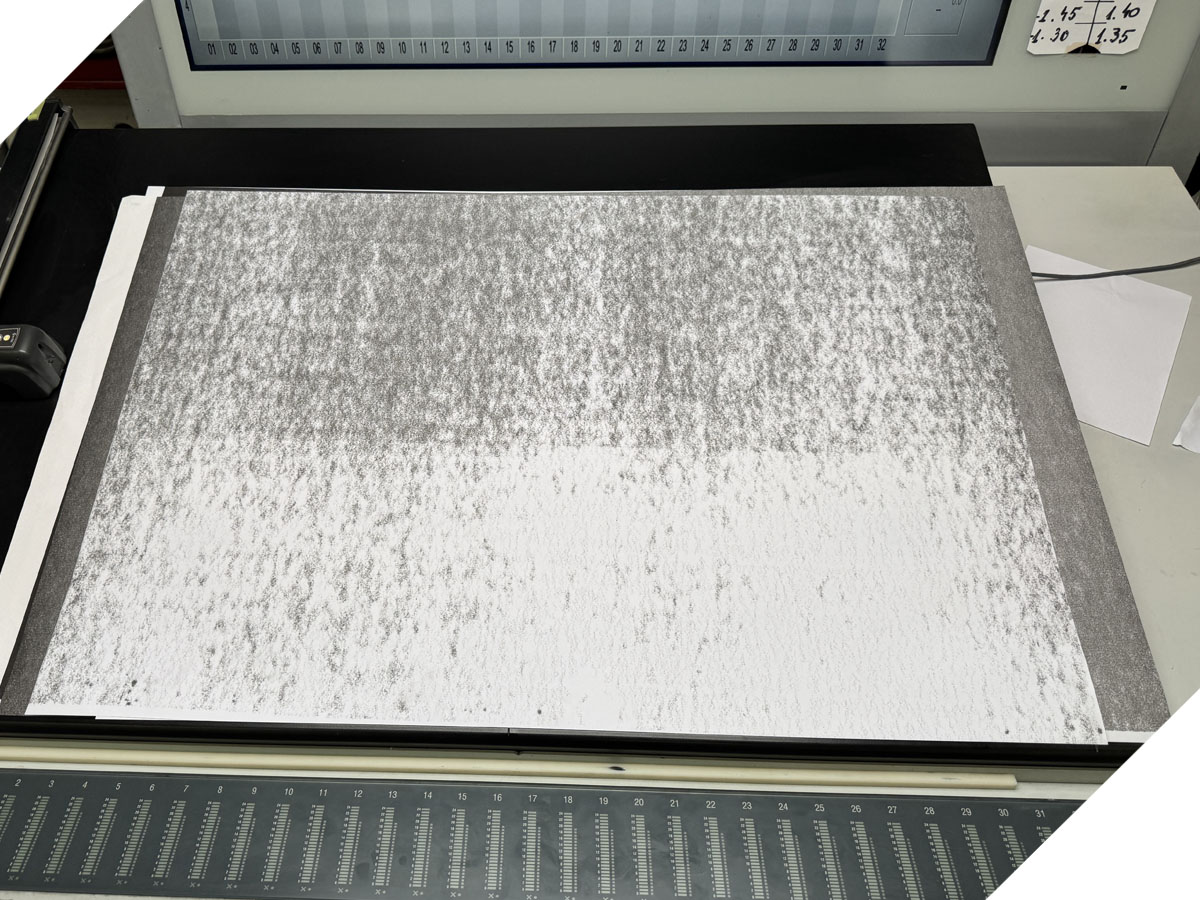

- Kiss-print test

- Print quality control on a random job

- Check of measuring devices

- Inspection of peripheral devices

- Issuance of certificate with photo and video inspection

- The test is free of charge for the owner if the buyer/dealer agrees to pay for the inspection.

- Finding a buyer is our concern

- For straight printing press

- Three working days incl. arrival and return

- All expenses within the EU

- Detailed inspection of all quality-relevant components

- Visual inspection of cylinder condition

- Kiss-print test

- Print quality control on a random job

- Check of measuring devices

- Inspection of peripheral devices

- Issuance of certificate with photo and video inspection

- The choice of most buyers. Determination of wear and tear, traces of previous incorrect assembly or installation defects

- For presses equipped with perfector

- Four working days incl. arrival and return

- All expenses within the EU

- Detailed inspection of all quality-relevant components

- Visual inspection of cylinder condition

- Kiss-print + Karo test

- Print quality control on a special test

- Check of measuring devices

- Inspection of peripheral devices

- Issuance of certificate with photo and video inspection

- All services described for standard test + special sheet feed test for long machines with perfector or for print shops with high demands on product quality

How is the price calculated?

Our rate

Compare these rates with the rates of the OEM technicians who work at 130-180 euros/hour.

Usually a STANDARD inspection is calculated on the basis of 1 working day + 1 day to arrive + 1 day to return home, at the rate of €600/working day.

An EXTENDED inspection is calculated from 2 working days + 1 day for arrival + 1 day for return, at the rate of 600 EUR/working day.

There may be an exception for inspections where it is possible to return home on the same day.

Standard

EUR 600 - day of inspection

EUR 600 - day to return

EUR 550 - flight costs within Europe

EUR 300 - car hire and fuel

EUR 250 - average cost of a hotel

EUR 150 - travelling allowances

Extended

EUR 1200 - two days of inspection

EUR 600 - day to return

EUR 550 - flight costs within Europe

EUR 400 - car hire and fuel

EUR 350 - average cost of a hotel

EUR 200 - travelling allowances

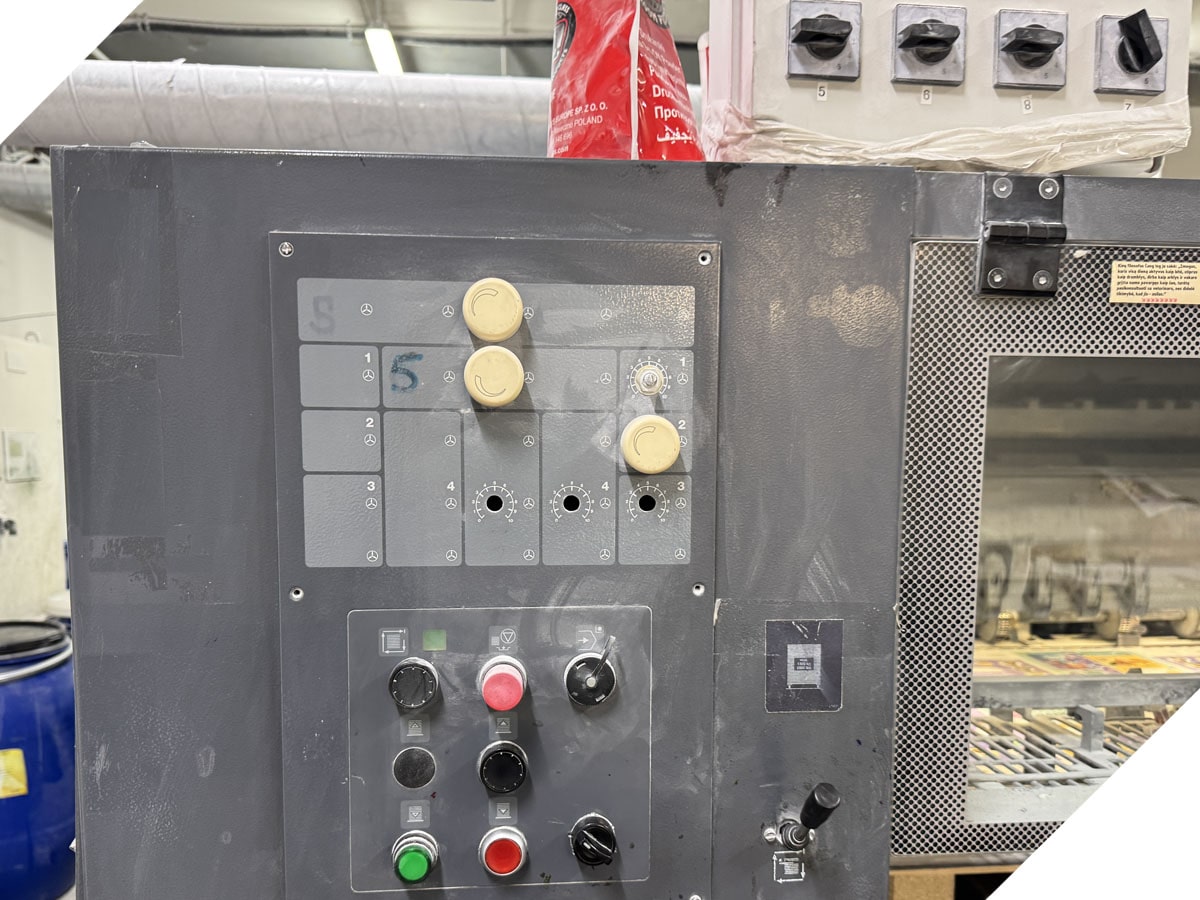

Do you see a tablet in the technician’s hand in the photo?

You’re not wrong. The inspector actually inspects the printing press in real time and immediately enters the inspection data into our online database in Google Forms. In the same database, he attaches the photos taken to confirm the results of the inspection.

Description Of The Inspection Process

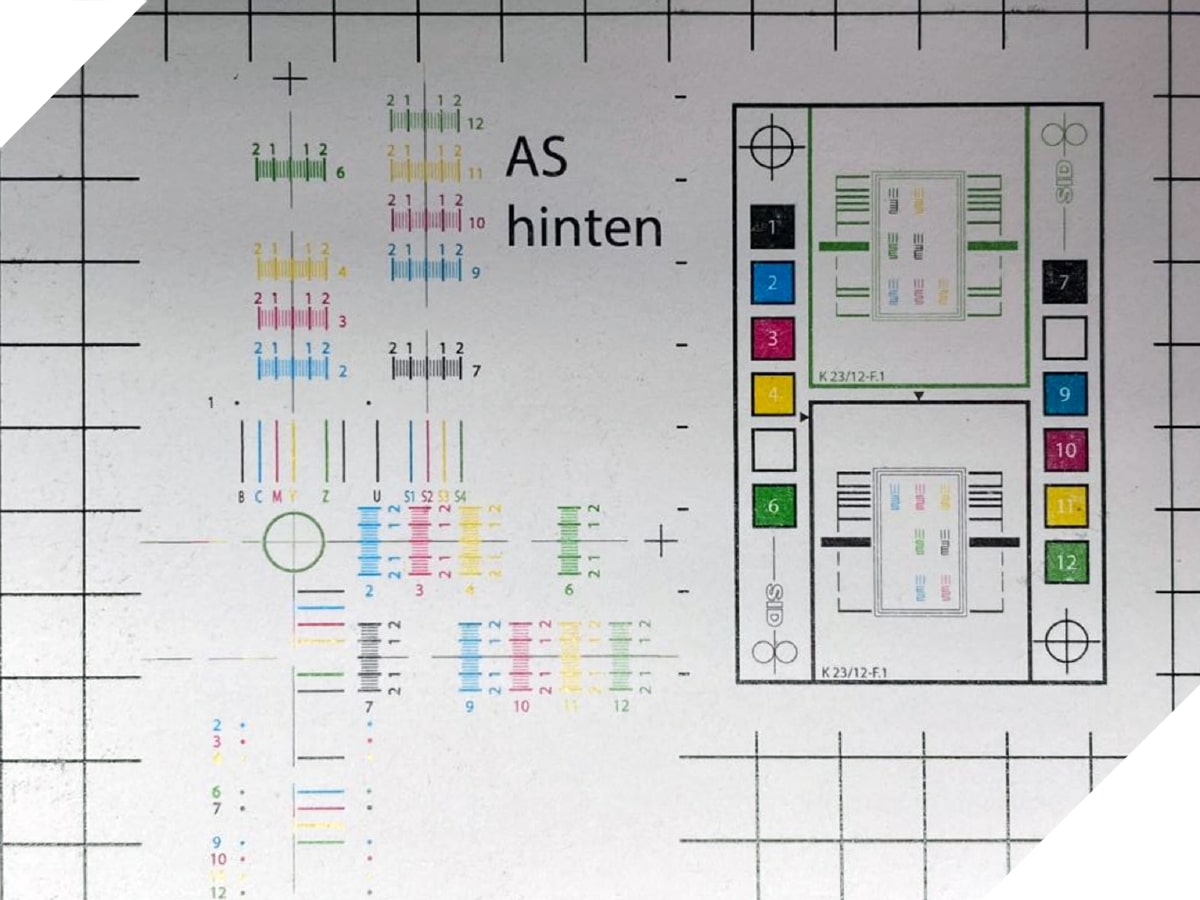

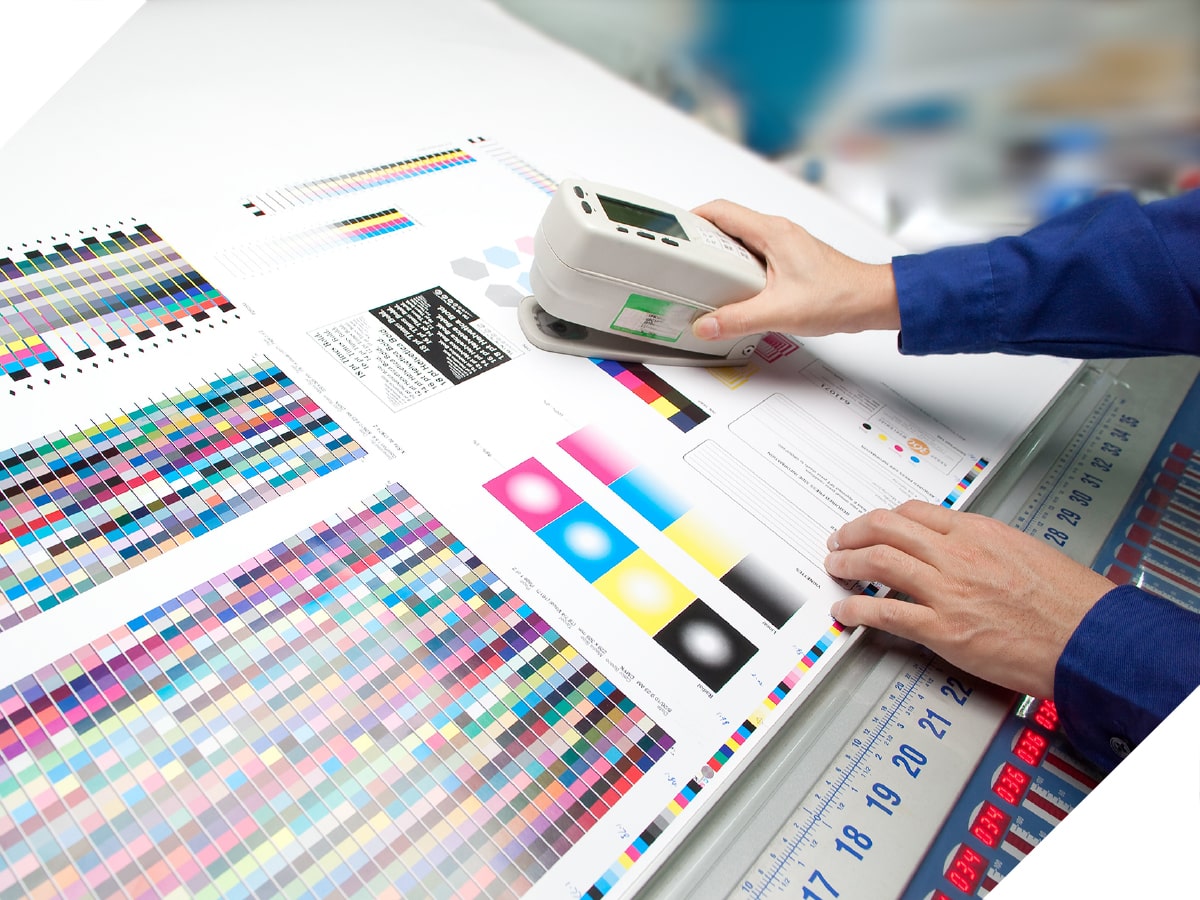

The equipment inspection consists of visually checking the condition of the machine, printing a kiss-print test to check the cylinder surface (if the machine is connected) and assessing its condition based on the work currently being printed on the machine. Upon agreement with the customer and the print shop, a CMYK scale can be printed to monitor the technological parameters of the machine.

The customer can follow the inspection online and make suggestions via WhatsApp.

Printing Tests

Complex jobs, such as the Karo test, are performed to check the condition of the perfecting unit on long, multi-colour printing machines.

Kiss-Print Test

Karo Print Test

Calibration Print Job

General Condition Test

We inspect the machine in the process of operation and fill in a special check-list, which describes the current state of the main units responsible for quality printing. We test the equipment not only in printing mode, but also when changing plates.

We will pay attention to the performance and condition of densitometric or spectrophotometric print quality control – Image Control, Axis Control, Inpress Control, ACR and others.

Software licences and the number of hours of dryer lamp operation are specified. In addition, special attention is paid to the maintenance of the machine, as the attitude of the operating staff also affects the overall condition of the machine.

Procedure duration: One working day

Amount of paper: not required

Requirements: It is desirable (but not essential) that the machine is in working order. You need a printer/operator in charge of the machine.

You can also use this service if you need to remotely inspect the machine, to attend the installation on your behalf.

The service includes one day for the engineer to arrive and one day to return home. The price includes the basic costs – flight, accommodation, car hire at normal times (if the visit falls on holidays, events, when the cost of expenses increases, we can adjust the cost of the service accordingly).