Implementation Of Lenticular Printing Technology

Baseline situation

A printing house operating in a large city and specialising in large format and offset printing decided to expand its range of services and offer its customers a new product – lenticular printing (3D images and animation effects). Until then, the company had no experience with this technology and was faced with the task of implementing it from scratch. The task of our technologists was to assist in launching the printing technology on the printer and on the sheetfed offset printing press.

Project Objectives

- To study the market and identify the demand for lenticular printing among current and potential customers.

- Purchase the necessary equipment and software for printing and postpress processing of lenticular images.

- Train employees on new technologies and processes.

- Create a portfolio and marketing strategy to promote the new service.

Each of our experts has training certificates from the Print Media Academy of Heidelberg Druckmaschinen, the company we have been working for for many years. So we can confidently say that we can take apart any Heidelberg printing machine, strip it down to its screws and tell you what each one is for.

We are available to help you with your printing technology needs or to advise you on the selection of a new or used machine. We have run technologies such as IML, lenticular printing, embossing on SM74 at various companies, so I would be delighted if my knowledge and experience could be of use to you. Just write and we will find a way to make you better than your competitors.

Procurement of hardware and software

To implement the lenticular printing technology, the printing company used:

- Computer-to-plate – the favourable Heidelberg Suprasetter 75 with three heads capable of outputting 400 lpi files as standard, necessary for correct lens separation.

- Sheetfed press – for offset printing, the print shop had a 2008 Heidelberg XL75-6-LX press with low mileage and UV dryers from IST.

- Lenticular rendering software Human Eyes from DP Lenticular, although there were options to turn to simpler solutions such as 3DProFect and Adobe After Effects with plug-ins) to properly create layered images for 3D effects and animation.

- Lenticular lenses and films – high quality printing materials needed to create the right effect.

Printing material selection

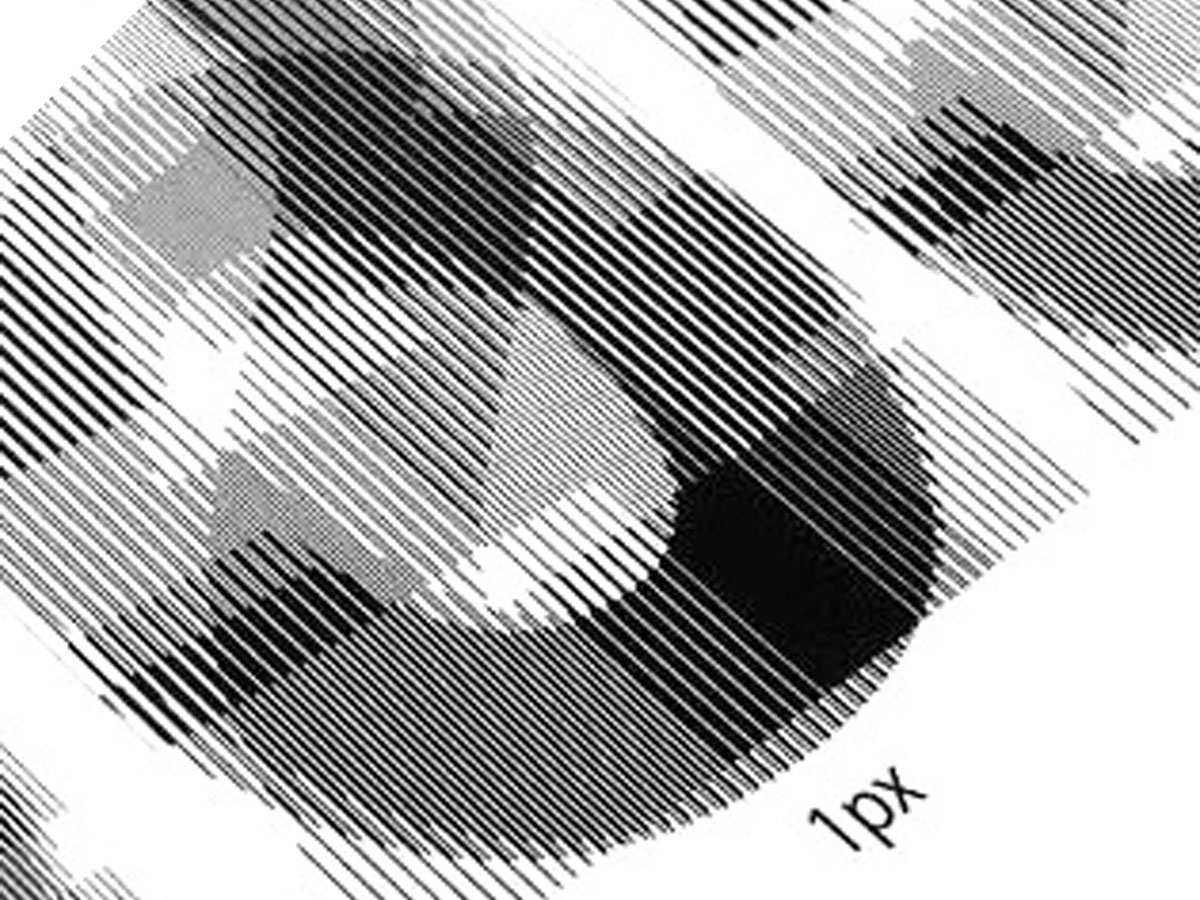

The characteristic of lenticular plastic is primarily determined by the resolution in lines per inch. The more lines per 1 inch, the thinner the plastic. For working on lenticular plastic, the model of the mould output device is extremely important. Most of the devices available on the market are not capable of producing high linework. Only devices from Kodak and Heidelberg were suitable. There was a Screen PT-R 3600 working in the printing house, which could not cope with the work. We had to turn to our neighbours and put the work on a Suprasetter 105.

Lenticular plastic with the following characteristics was purchased:

Number of lenticulars per 1 inch – 75 lpi

Thickness – 0.6 mm

Lens pitch – 0.3364

Viewing angle – 38 degrees

Viewing distance – 0.15-1.8 metres

Suitable for all effects: 3D, Flip effect, Animation, Morph, Scaling.

Portfolio creation and marketing

The work to launch the new for the print shop took a total of about 2 months. The main difficulty was to select the right equipment that would be able to cope with the task.

As a result of preparations to bring an unusual technology to the market on an industrial scale, the printing company created a portfolio with examples of work, including samples with various lens effects (morphing, 3D, flip). Presentations were organised for key clients and agencies. We also helped to properly launch an advertising campaign on social media and at specialised events in the field of printing and advertising, promoting the new direction.

Subsequent development

After a few years, the company found that while demand for lenticular images was stable, print runs began to decline. Today, digital technology allows images to be printed on inkjet printers and then laminated to a lenticular lens. The decision was made to purchase a digital device.

Subsequently, after long-term testing, the best work was recognised as being printed on an Epson Stylus Pro 9600 with Onyx PosterShop bitmap processor using UltraChrome ink. Using a Seal Image 600 laminator, the resulting image was adhered with MacTac’s Permaclear thin clear double-sided adhesive tape to lenticular plastic from Microlens. This result was comparable to the print quality of a sheetfed offset press.

Nevertheless, the print shop still uses the solution implemented by our specialists for packaging production. Lenticular is not easy to print, as you need to have certain experience and equipment. Such a product is considered high-tech and can be sold with higher added value.

Due to the successful implementation of the innovative technology, the printing company has strengthened its position in the market as a company offering high-tech solutions. This has increased brand recognition and increased trust from existing and potential customers.

Conclusions

The successful introduction of lenticular printing technology was made possible by a well thought out plan including market analysis, staff training, testing and active promotion of the service. The printing company not only expanded its range of services, but also occupied a new niche, which increased profits and attracted new customers.

Contact PressInspection.com specialists if you are facing the task of launching a new technology that you are not familiar with. We may be able to help. And your competitors won’t know about it.

- Note 1. On our website we respect the principles of confidentiality. We are keenly interested in the development of our clients, who would not be very happy with the emergence of competitors who want to repeat their experience.

- Note 2. The point of the case study is for our potential customers to familiarise themselves with our company’s experience. Blind copying of the case study will not lead to a positive result, as each business, as well as location, is purely individual.