Performing the Kiss-print test

We provide you with instructions on how to perform the test in case the cylinders of your printing machine have been damaged and then repaired. You need to understand how well the work was done and accept the work of the repair team.

The test is called ‘Kiss-print’ because the cylinders touch each other with minimal pressure, as if in a kiss. It allows you to detect hidden defects on the surface of printing and offset cylinders. The use of new offset rubber blankets and backing sheets is a mandatory requirement.

The purpose of the test is to check the condition of the surfaces of the plates, rubber and impression cylinders, the condition of the cylinder bearings and the compliance with the set pressure values of the lower printing pair (rubber and impression cylinders).

Recommended Offset Blanket Tension

|

Maximum format of the press, mm |

Tension, Nm |

|

B3 (350×500) |

30-35 |

|

B2 (540×750) |

40-45 |

|

B1 (720×1050) |

55-65 |

|

A0 (1200×850) |

65-70 |

|

B0 (1000×1600) |

65-70 |

Tension For Different Models

|

Printing Press Manufacturer And Model |

Total thickness = calibraied sheets + blanket, mm |

Blanket Tension, Nm |

|

MAN Roland 200/ 300/ 500 |

2,30 |

40-45 |

|

MAN Roland 700 |

3,25 |

50-55 |

|

MAN Roland 800/ 900 |

3,25 |

65-70 |

|

Heidelberg SM102/ CD102 |

3,25 |

65 |

|

Heidelberg XL105/ XL106 |

3,25 |

65 |

|

Heidelberg SM72/ SM74/ SX74 |

3,25 |

40-45 |

|

Heidelberg CD74/ XL75 |

3,25 |

40-45 |

|

Heidelberg GTO46/ GTO52 |

3,25 |

30-35 |

|

Heidelberg SM52/ SX52 |

3,25 |

30-35 |

|

KBA Rapida 74 |

3,20 |

40-45 |

|

KBA Rapida 105/ Rapida 106 |

3,20 |

60-65 |

Test duration: 1 hour

Amount of paper: 200-300 sheets of full format, 130-150 g/m2

Requirements: New blankets and underlay sheets installed.

Blanket tensioning is performed with a torque wrench (tightening torque depending on the press model).

Print cylinders must be thoroughly cleaned of dried ink and other contaminants.

Plates are arbitrary.

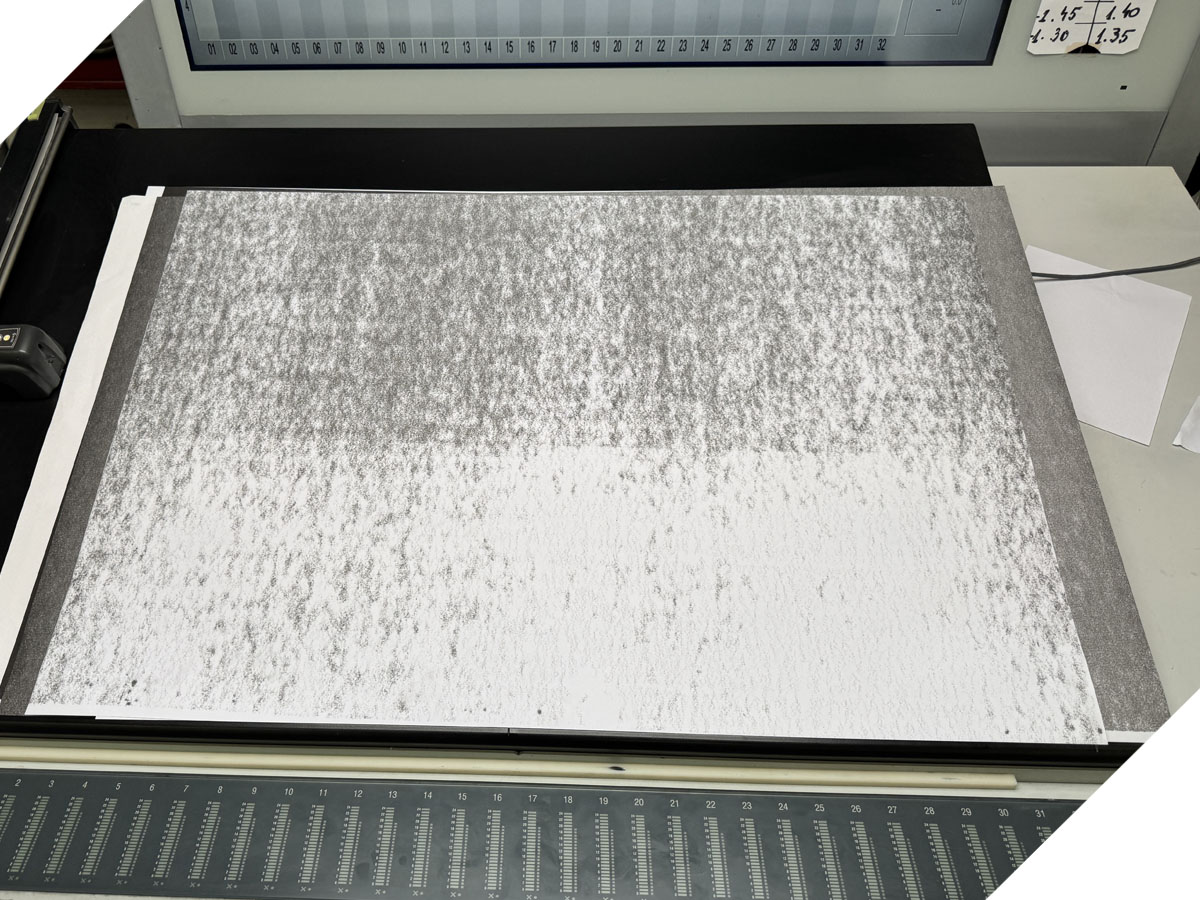

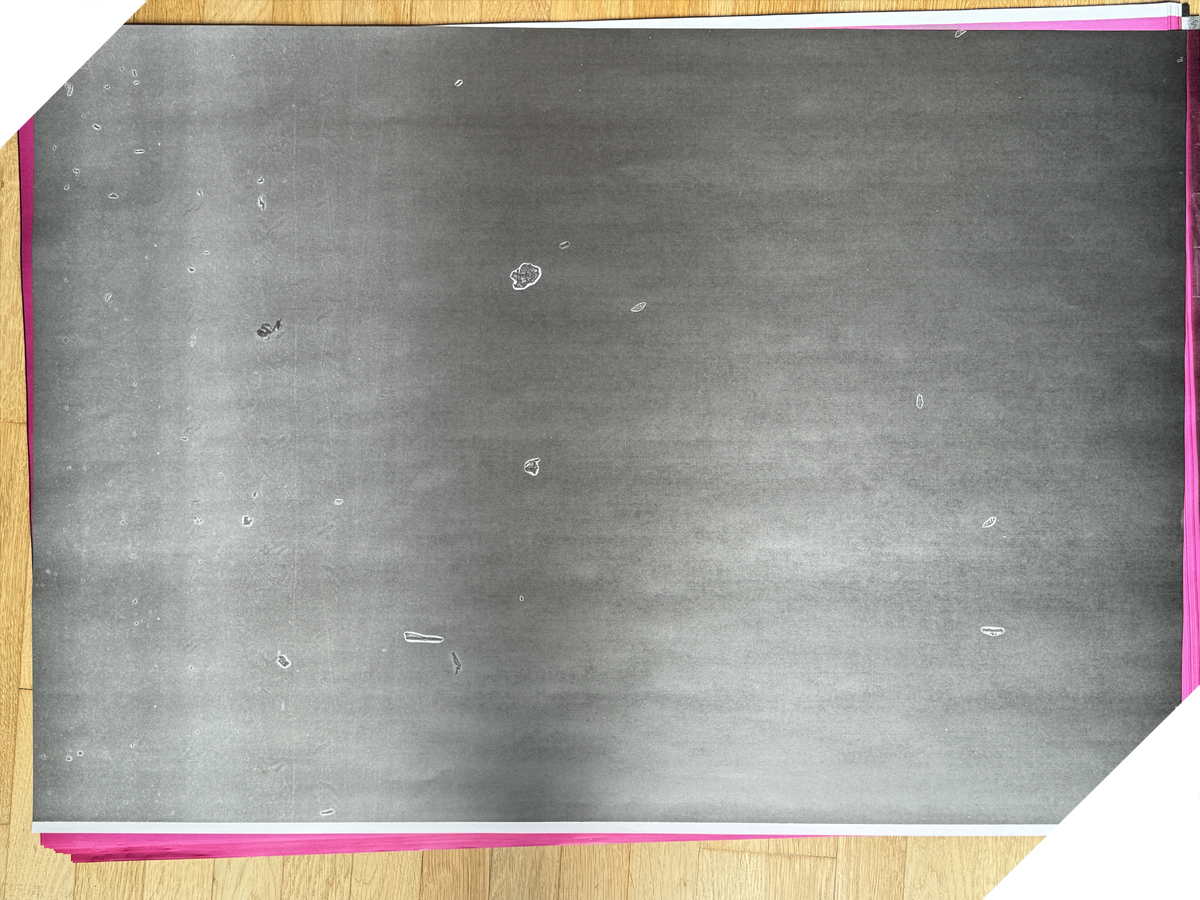

Invisible Defect on the Printing Cylinder

Debris on the blanket

It is necessary to wash-up the cylinders, clean the offset blanket and print the test again.

Kiss-Print Test

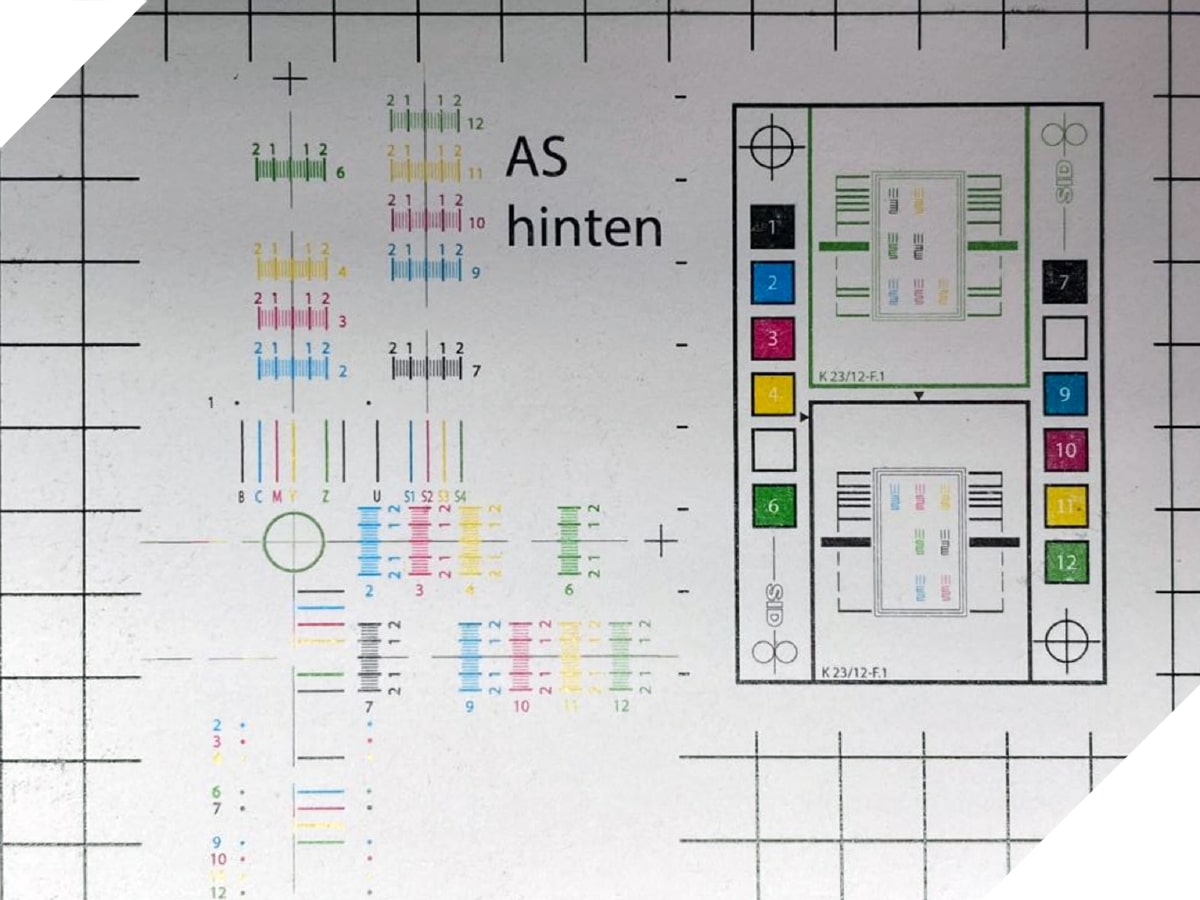

Karo Print Test