Print Process Test

Important: this test alone does not give a complete picture of the technical condition of the machine, as the print parameters to be checked are mainly related to the technology and consumables used by the print shop.

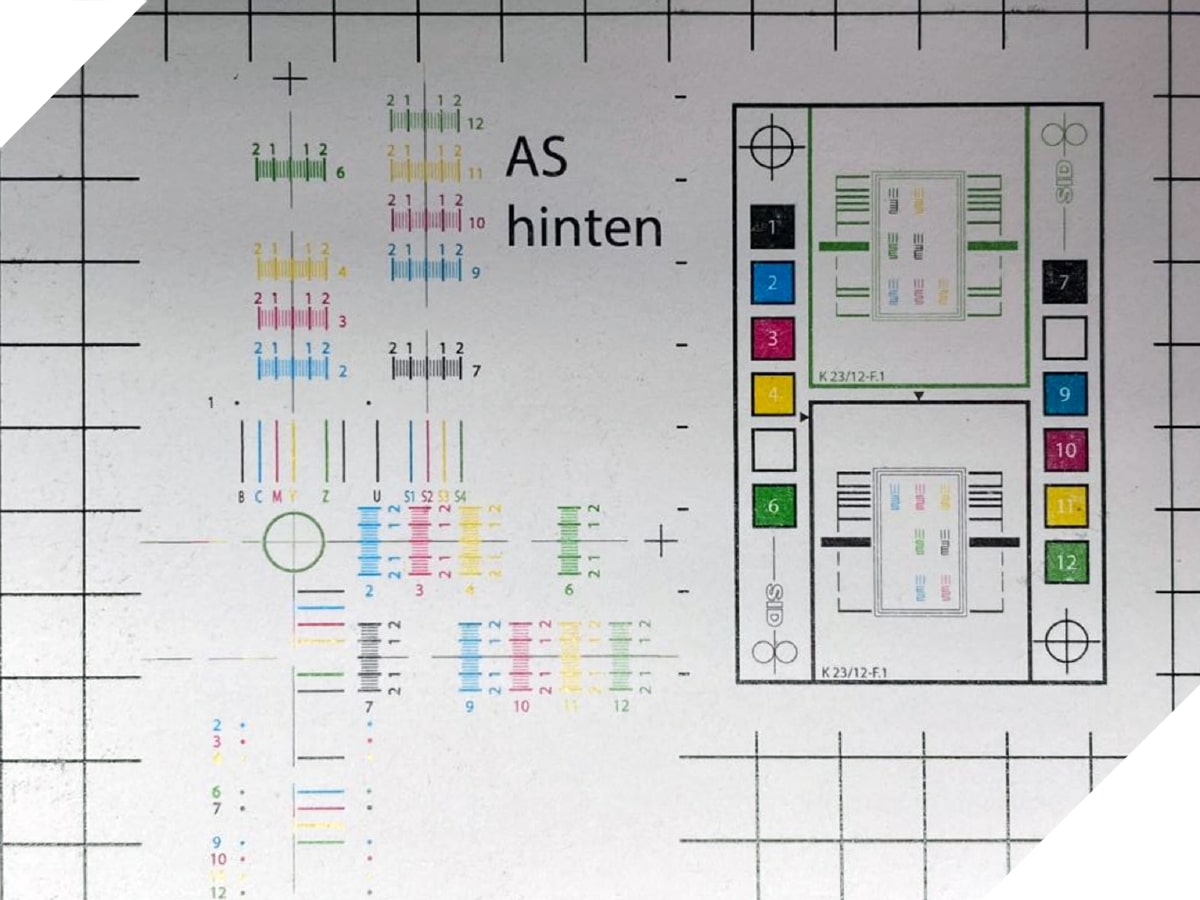

The calibration scale is the same test that is familiar to the average printer and requested by printing house owners.

This test is used to calibrate the printing process and calibrate the printing machine control device, such as Axis Control, Image Control, Densitronic S, and LITHEC Lithoscan Professional.

Of course, this test also reveals some defects in the sheet transfer system and the turning device. However, it is not suitable for testing a used machine – it primarily demonstrates the technological features of a particular printing house.

Procedure:

During test printing, achieve optimal registration alignment and check the operation of the spectrophotometric device and powder sprayer. Pay attention to additional printing parameters. Set aside at least 5 test sheets and mark them as in the previous tests.

Test duration: 1-2 hours

Amount of paper: The required number of sheets is 100-150 per unit.

Requirements: Blankets tension checked with a torque wrench.

BCMY ink order.

If a perfector unit is present, it is mandatory to use units before and after it. Printing in 4+0 mode.

Printing is performed from the file issued by us. Applicable screening is 150 l/inch.

Printing speed 70% of the maximum press speed.

Required amount of paper 200-250 sheets per unit.

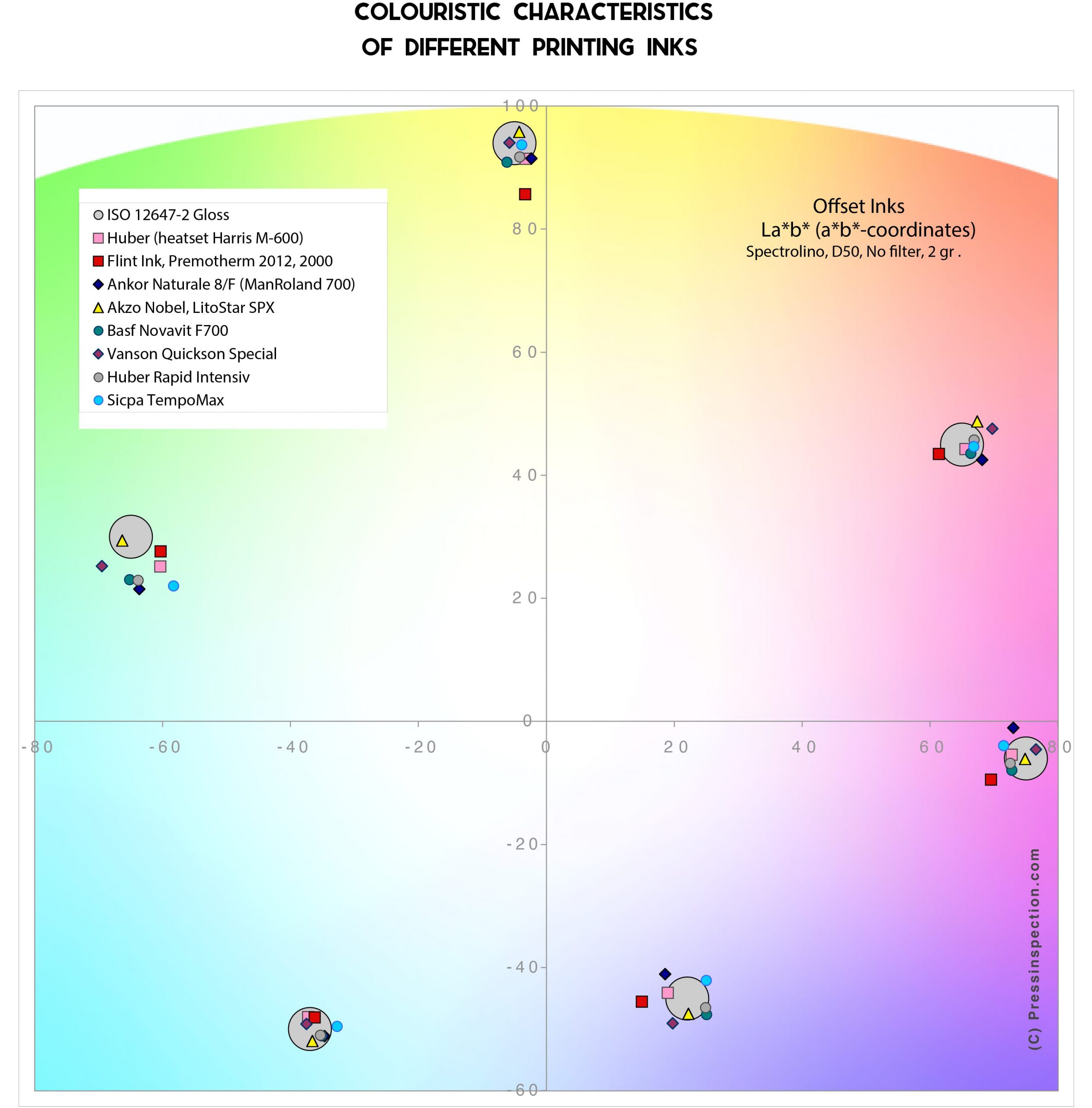

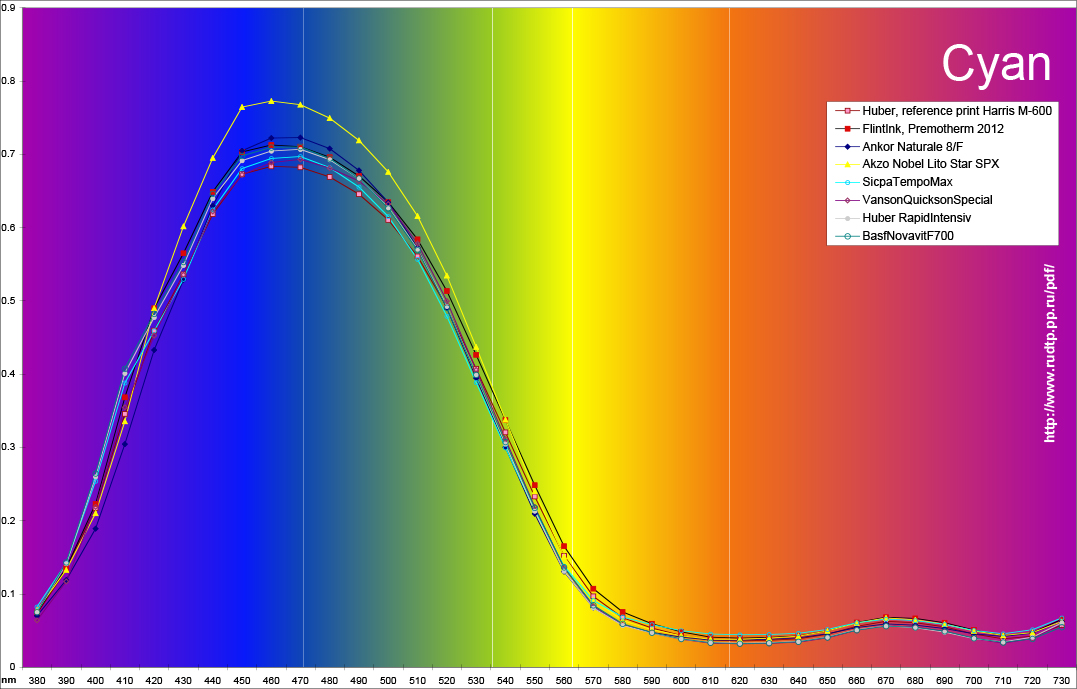

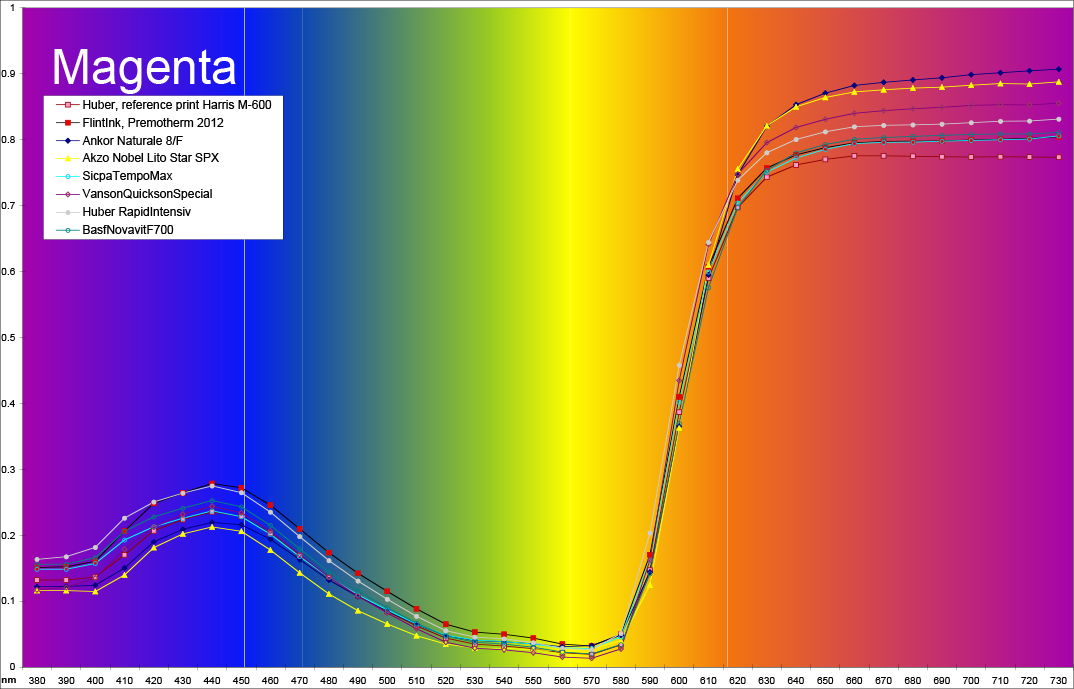

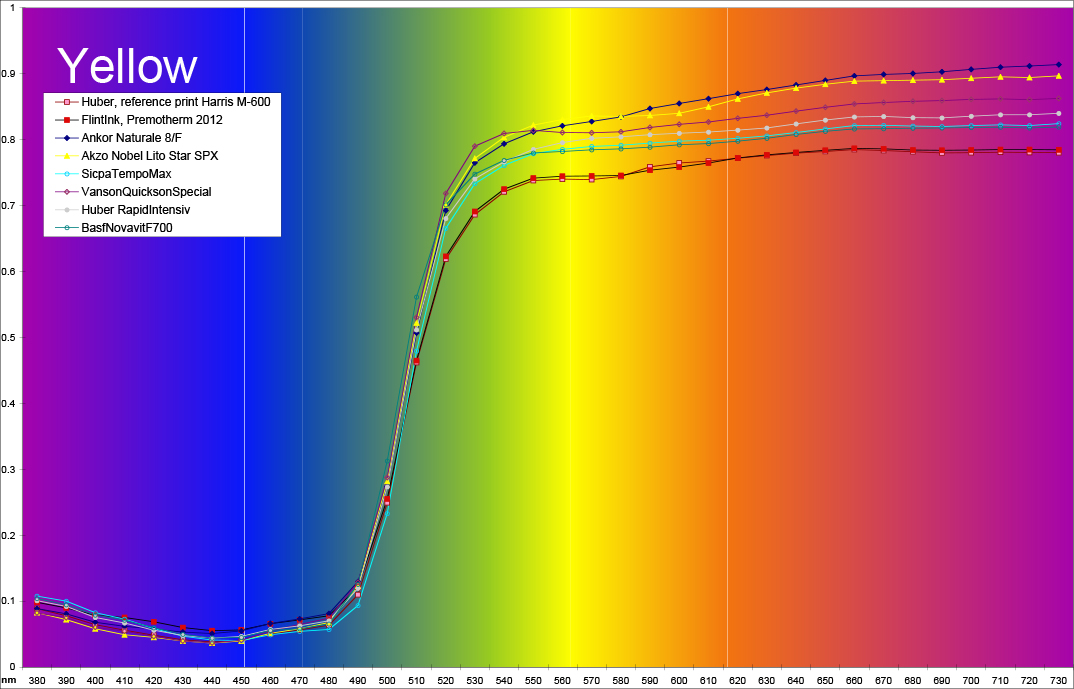

Colouristic characteristics of different printing inks

This problem has been recognised for a long time. At one time, GretagMacbeth specialists conducted a number of tests, compiled the colour characteristics of the different paints available at the time, and created a spectrum map.

The diagrams show the comparison of different colours with the ISO-12647-2 standard when measured on black and white.

Measurements were made on Gretag Macbeth Spectrolino, D50, No filter

© Alexander Pylsky, Mikhail Sartakov, cielab.xyz

Kiss-Print Test

Karo Print Test