Recently, one of our readers approached me with a simple question:

“What do you tell me about the KBA Rapida 75? IIt seems to be a decent machine at a reasonable price, manufactured by a reputable company.”

Indeed, on these pages we often discuss Heidelberg presses. What about the others? The market might seem dominated by one manufacturer, and competitors have long fought for a place beside it. Of course this is not true. During my own years with Heidelberg, we constantly faced the pressure of lower-priced machines from rivals. Time to look back and ask: did those alternatives stand the test of time?

By coincidence, we recently inspected two identical KBA Rapida 75 presses, both built in 2008, with consecutive serial numbers. What we found was revealing.

To say it in advance: these presses proved temperamental. As they aged, a remarkable number of recurring faults appeared. As problems were discovered, KBA tried to fix them, but this only happened in later models. Judging by the service history of the units we examined, the Rapida 75 has turned out to be a printing machine with a notably high cost of ownership.

But let’s start at the beginning.

Origins of the Rapida 75

Our story will not be so much about the Rapida 75, which unexpectedly changed its target audience and led to serious changes in the printing equipment market as a whole. Let’s take a look at how the Rapida printing press line has developed over the course of its existence – this will give us an opportunity to understand why KBA never returned to the packaging market in the half-format printing press segment.

The history of the Rapida series began long before 2008, when the first Czech machine appeared.

König & Bauer has been showcasing sheetfed printing presses under the Rapida brand since the late 1960s, and by the early 1990s it already had a full range of formats — from the half-format Rapida SRO 72 (52 × 72 cm) to large-format models.

The late 1980s were a turning point: printing equipment became faster, electronics more reliable, and manufacturers began abandoning the old planetary and tandem configurations in favor of the now-standard unit-type design.

Contrary to popular belief, the so-called planetary configuration—with a common impression cylinder (CIC)—was notinvented by Planeta or even KBA. The name Planeta itself came from the planetary gear train, not from a “planetary” layout of satellite printing units around a central cylinder.

The Rapida 72: A Reliable Workhorse

Around 1990, KBA replaced its outdated planetary SRO with the unit-type Rapida 72. The new model has got the maximal speed of 15 thousand impressions per hour ran faster and far more stably. These sturdy “workhorses” gained a reputation for simplicity and low cost. They came with automatic wash-up devices, optional densitometric control, and a short inking unit with 14 rollers.

Users noted the perfection of the electronics in the new series of machines and their technical equipment. The new machine was both simple and well thought out. The ‘7 o’clock’ cylinder design allowed fairly thick cardboard to be processed without dirtying the rear edge of the sheet. Most breakdowns were minor, and the machine could be repaired ‘on the spot’. But most importantly, the sectional layout allowed for a significant increase in the machine’s operating speed.

The only drawback worth mentioning is the short inking unit. KBA’s philosophy was that it should be both responsive and high-capacity. The inking unit had only 14 rollers, albeit with a large diameter.

This feature turned out to be both an advantage and a disadvantage. But alas, nothing in this world is universal. On the one hand, it allowed for quick cleaning and ink changes, but on the other hand, it made it difficult to reproduce large solid areas during long runs.

Operators complained about the appearance of patterns, and the ink did not hold well. KBA disagreed with these opinions for many years, and the concept remained in place until the end of production of the Rapida 74 series.

The Colortronic console offered standard features typical of the early 1990s: side and circumferential registration, colour zone adjustment and general machine diagnostics.

Non-functioning printing units could be switched off individually. Thanks to double-diameter cylinders, the printing press could handle materials up to 0.8 mm thick, which made it popular with packaging manufacturers.

Interestingly, the old SRO72 model did not disappear completely: in 1995, KBA introduced the Rapida 72 K, a two-colour version based on it. Marketed as the fastest sheetfed printing press in the world, it even made it into the Guinness Book of Records for achieving a speed of 18,000 impressions per hour in the late 1990s.

The Rise of the Rapida 74

With the dawn of the CIP3 era, the Rapida 74 became the logical successor to the printing press, with a slightly larger sheet format (52 × 74 cm), higher speed (15,000 sheets per hour) and more configuration options, including varnishing, double-sided printing and others. It was unveiled in a new design at DRUPA 2004 and immediately attracted attention with its modern appearance.

This model became the swan song of KBA Rapida half-format presses throughout their entire history. Even today, these presses remain relevant.

In this model, KBA also offered an optional economical ink fountain system with dividers. If the customer planned to print jobs with rainbow effect, he could load several colours into one ink fountain and use them for special jobs, such as printing secure documents, where axial oscillation can be disabled.

In the mid-2000s, KBA experimented with waterless offset, launching versions with the Gravuflow short inking unit (covered earlier on PressInspection).

The relative simplicity of the design with effective technical solutions, as well as an affordable price at 70% of the Heidelberg price, made this model quite popular in its early years. Printing machines manufactured between 2004 and 2008 are still in demand and often sell for higher prices than some newer generation models.

Why Production Moved to the Czech Republic

Compared to Heidelberg’s CP2000-equipped machines, the Rapida 74 lagged technologically, but its true problem was cost of manufacturing.

By the mid-2000s it had become expensive to produce in Germany: high labor and assembly costs forced KBA to seek a cheaper B2-format platform. The company couldn’t price the 74 against Heidelberg—it was simpler in design and aimed at a different buyer.

The model’s commercial failure coincided with the bankruptcy of Czech manufacturer Polly in Dobruška—the same town where ADAST had once built presses. In 2005 KBA purchased the facility, its engineering documentation, and staff, turning it into KBA-Grafitec. All B2 production was moved there.

An internal report I once saw stated that only seven Rapida 74 printing presses were assembled in 2007, after which production in Germany was discontinued.

The Rapida 75 was introduced in 2008. Objectively speaking, it was not a 100% German machine. In fact, for some time, KBA even continued to produce the old Polly and Performa models under its own brand and in new colours, gradually modernising them. These included the Rapida 75 and 75E, followed shortly afterwards by the 75 PRO. At the same time, the Performa 66/74, a machine typical of the Czech Republic and intended for entry-level printing houses, remained in production.

Thus, the Rapida 75 became the cost-optimised successor to the German 74, combining KBA’s experience with the simpler design of the Polly, with an emphasis on compactness, affordability and moderate automation.

Launch of the Czech-Built Rapida 75

The Rapida 75 made its debut at drupa 2008, and then active deliveries began in Europe and the United States.

Technically, it was familiar to novice printing houses from Polly factory products: a compact frame, continuous gear drive, 7 o’clock cylinder geometry, double transfer cylinders, a maximum speed of 15,000 sheets per hour and formats of 530 × 750 mm (optionally 605 × 750 mm). Configurations ranged from 2 to 8 colours, with optional double-sided printing and varnishing.

In 2011, the Rapida 75 E was introduced, a more affordable version that made it easier for small print shops to enter the market, and in 2016, the Rapida 75 PRO with a larger sheet format, TouchTronic console, faster makeready and partial standardisation with larger Rapida models.

However, consumers did not appreciate the sharp change in direction – after the high-tech Rapida 74, the company switched to entry-level machines, which were once operated by ADAST Dominant 700 and later by Polly. And already in 2012, KBA acknowledged that the ‘small-format Rapida 75 manufactured by KBA-Grafitec’ had not met sales expectations. The reasons given for the reduction in production were fierce competition and a decline in the number of printing houses working in B2 format. Nevertheless, KBA did not abandon the production of half-format machines.

Although the company’s hopes shifted to the more automated Rapida 76, which appeared in 2013, these machines never achieved the popularity of the Rapida 72 model.

Heritage of Polly / Performa

But let’s return to the Rapida 75, which was produced from 2008 to 2012. Although the machine was positioned as a state-of-the-art solution from Koenig & Bauer, its Czech origins were obvious to everyone. It was still the same lightweight, compact design of a half-format printing press from Polly, optimised for economical print runs and quick preparation for printing.

Many mechanical solutions and maintenance methods were inherited directly from the Dobruška factory — feeders, sheet transport, lubrication system, even component suppliers. But with the factory’s transition to KBA, the plant gained new suppliers and a quality control system.

So What Was the Rapida 75?

From an analytical point of view, the launch of the Rapida 75 was KBA’s last attempt to stay in the B2 segment. However, printing companies often noted the higher downtime and cost of ownership of the 75 compared to competing Heidelberg SM74 or MAN Roland 202 printing presses of the same format. Although such opinions mainly come from user forums rather than factory data, they show how the market perceived this model.

But most importantly, users were puzzled by the fact that KBA had previously targeted advanced users, especially packaging manufacturers, but suddenly changed its target audience. The Rapida 75 marked a return to a simpler, entry-level concept for beginners. This is how it was perceived by the market.

KBA’s sudden exit from the premium B2 machine segment gave a boost to sales of Japanese Ryobi machines, particularly the 784 and 700 series. So much so that it even affected MAN Roland’s sales. But we’ll talk about that another time.

Almost 20 years have passed since the start of production of the Rapida 75, which significantly changed the market for half-format machines from all manufacturers. We can now look back on it with the benefit of hindsight and identify its advantages and disadvantages that have become apparent over the years of operation.

Strengths of Rapida 75

-

Very compact footprint and compatibility with CIP3/CIP4 format

-

Low declared power consumption

-

Rated speed up to 15,000 impressions per hour

-

Flexible configuration: 2–8 colors, perfecting, coating, and optional US format (605 × 750 mm)

-

In the PRO version — faster makeready and modern interface

-

Laser-zoned duct blade, reducing uneven wear

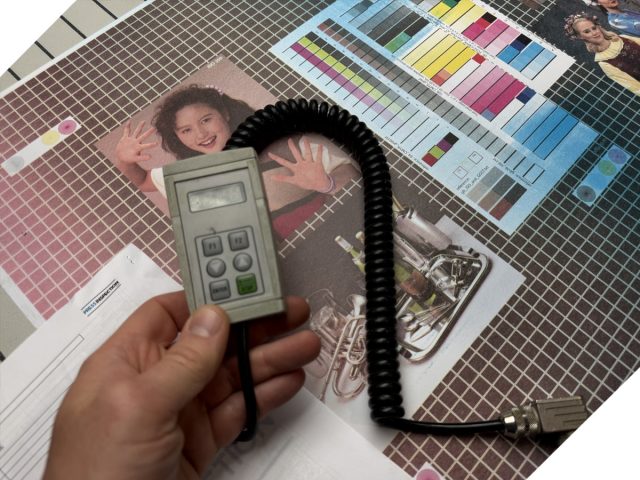

A major advantage of this laser zoning is that the screw presses an entire segment against the surface of the doctor blade. Previously, when laser cutting was not possible, the screw bent the surface of the blade, which over time formed a groove on the surface of the cylinder. - Dedicated calibration tool for ink sones included. This very useful tool is necessary if the printing press uses to CIP3 format to receive data from prepress.

This type of device is used not only by KBA, but also in some MAN Roland machines.

Weaknesses of Rapida 75

-

The model was outdated from the outset, with mostly mechanical adjustments. Preparing for printing took longer and resulted in more waste. Given the rising cost of labour in Europe, this model could only find a market in certain countries where printing speed was not a priority. KBA itself later acknowledged in its brochures on the Rapida 75 PRO that it was only through the introduction of automatic plate mounting, the more advanced CleanTronic washing system and DensiTronic control that it was able to reduce waste and start-up time.

-

The feeder design, with rollers and brushes plus two vacuum belts, was already outdated in 2008 and sensitive to paper trimming accuracy.

-

-

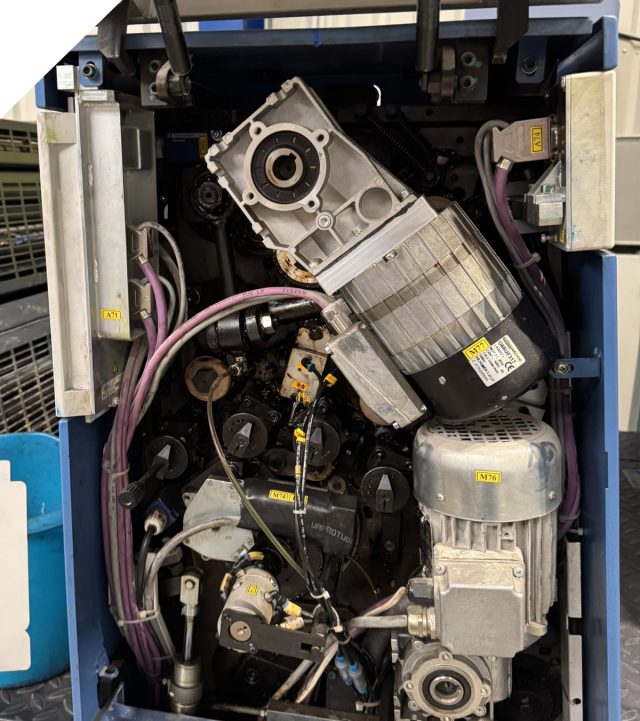

- The plastic parts are already badly worn after 20 years. Torn dust caps on the drive shafts of the self-loading head are a common issue on all of the printing machines we’ve checked out. But that’s not the worst of it. This applies to all plastic parts and gears. Even in the Technotrans refrigerator cabinet, the coolant hose connectors are fragile and often fail suddenly.

-

-

-

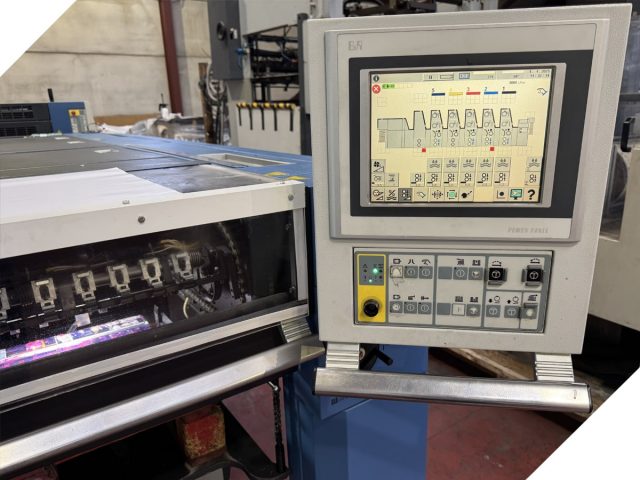

- The machine’s ergonomics are primitive: peripheral devices are not connected via CAN bus. The controls are located in different places: colour zones are controlled from the Colortronic console, while the powder device, dryer and other peripheral devices are switched on from the colour TFT-panel at the delivery…

-

-

Manual lubrication required at numerous points; forgetting it led to wear, play, and sheet loss inside the press. Strangely enough, this problem was observed on ALL first-generation Rapida 75 printing presses manufactured between 2008 and 2010 that were inspected.

-

Limited availability of spare parts: small production run means many sensors or motors must be ordered individually from KBA with long lead times.

-

Electronics proved unreliable; registration motors in print units often failed.

-

New motors are expensive and cannot be found on the secondary market. One well-known dealer of printing equipment even concealed faulty motors during a demonstration of his printing machine at his warehouse before our inspection.

-

On all 2008 machines inspected, the Baldwin dryer monitor was damaged.

-

Failures of ductor drive motors are widespread; it is said that replacements now cost around €6,000 each and exist only in old stock.

-

Sheet-loss incidents inside the delivery section occasionally led to fires when unnoticed. It is also very telling that the problem was found on both inspected machines of the same generation.

Resale Market

On the secondary market, the Rapida 75 has consistently fetched lower prices than the “icons” of its class (Heidelberg SM/XL 74, Komori Lithrone 28/29).

This reflects its positioning as an economical semi-format press from Dobruška—bad news for sellers, but a plus for bargain-hunters.

Conclusions

Essentially, the KBA Rapida 75 was KBA’s Czech attempt to maintain its position in the half-format machine market. The model was born out of the Polly/Performa engineering developments and was conceived as an inexpensive alternative to the expensive German RA 74.

Designed for entry-level printing houses, it was simplified both mechanically and electronically. The inherited Czech design inevitably affected its durability: after a few years of operation, weaknesses began to appear.

The machine was adequate for the entry-level market, but like any primarily mechanical printing machine, it required disciplined maintenance. Many owners neglected lubrication or dismantled unused units for spare parts.

As a transitional generation, the 75 found itself between two eras — its weak points were later corrected in the 75 PRO and 76. When choosing a printing press today, I would rather pay attention to the earlier Rapida 74 or the later Rapida 76.

If you come across a ‘bargain’ Rapida 75, approach it with caution. A well-maintained example can still print beautifully, but it will not be cheap to run. Expect a price similar to that of a Speedmaster SM 74. However, all other things being equal, a Heidelberg in poorer technical condition remains the safer choice.

Every Rapida 75 on the market deserves a thorough inspection: any malfunction can cost not only money, but also weeks of downtime.

In short, despite the minimal electronics and the large number of weak points of this printing machine

By the mid-2010s, this model had naturally given way to the 75 E / 75 PRO, and technological leadership in the B2 format had passed to the Rapida 76 — but that, as they say, is another story.

(c) PressInspection — Independent analyses and inspections of printing equipment.