For decades, Heidelberger Druckmaschinen AG has been a trendsetter in printing technology. However, like any dynamic company, Heidelberg has had to adapt to changing market realities. In the early 1990s, the decision was made to discontinue production of the T-Offset sheetfed offset press and replace it with a more modern and versatile model, the Quickmaster QM 46.

Reasons for discontinuing the T-Offset

Although the T-Offset was a reliable and compact machine, it was based on outdated design concepts. It was a single-colour offset machine with a simplified feed system and a primitive inking unit, designed more for simple printing tasks. By that time, customers were demanding more: short runs, high quality, colour prints and fast turnaround. In addition, the evolution of Heidelberg’s approach to mini-print shops played an important role. This led to the concept of the ‘Quick Print Shop’ – a small, modern print shop comprising a CTP solution for plate making, a Quickmaster printing machine and a Polar 66 cutting machine. All this could be accommodated in less than 50 m².

Although the T-Offset was a reliable and compact machine, it was based on outdated design concepts. It was a single-colour offset machine with a simplified feed system and a primitive inking unit, designed more for simple printing tasks. By that time, customers were demanding more: short runs, high quality, colour prints and fast turnaround. In addition, the evolution of Heidelberg’s approach to mini-print shops played an important role. This led to the concept of the ‘Quick Print Shop’ – a small, modern print shop comprising a CTP solution for plate making, a Quickmaster printing machine and a Polar 66 cutting machine. All this could be accommodated in less than 50 m².

The main difference between the Quickmaster QM 46 and its predecessor is its high degree of automation. An automatic plate setting system (instead of optional trays for T-Offset) has been added as standard. The offset cylinder has been equipped with an automatically connected quick wash device. To access it and drain the used chemicals, all you had to do was open the side cover and pull the wash module towards you.

The paper was easy to load into the machine thanks to the very convenient access. A new, very simple and modern control console was introduced. Overall, the machine looked modern and attractive, and it was really pleasant to work on.

Demonstration of the new concept

To promote the Quick Print Shop idea, Heidelberg organised an unusual marketing campaign: the equipment was installed in a special demonstration bus and driven directly to the customer. This solution was devised many years ago by Hubert Sternberg so that the printing machine could be shown even in places that are difficult to reach by conventional means, and was demonstrated in various countries. The bus was actively used in the 1990s not only in Central Europe, but also in Ukraine, Belarus, Kazakhstan and Russia. This format allowed potential customers to see how all the equipment could work effectively even in mobile or confined conditions.

To promote the Quick Print Shop idea, Heidelberg organised an unusual marketing campaign: the equipment was installed in a special demonstration bus and driven directly to the customer. This solution was devised many years ago by Hubert Sternberg so that the printing machine could be shown even in places that are difficult to reach by conventional means, and was demonstrated in various countries. The bus was actively used in the 1990s not only in Central Europe, but also in Ukraine, Belarus, Kazakhstan and Russia. This format allowed potential customers to see how all the equipment could work effectively even in mobile or confined conditions.

You can read about the history of demonstration buses in printing at the link.

The Quickmaster 46 machine used not only standard offset plates, but was also capable of working with paper and polyester plates. Short 12-roller inking unit was more advanced than that of the T-Offset, but still limited in terms of adjustment accuracy. An automatic offset blanket washing device was standard equipment. The two-colour version featured sequential printing, which allowed simple two-colour production in a single pass. Formats up to 34×46 cm were supported with narrow-side sheet feeding, which made the machine attractive for small printing houses producing forms, business cards and flyers.

Construction of Heidelberg Quickmaster QM 46

The Heidelberg Quickmaster QM 46 was released in two versions: single-colour (QM 46-1) and two-colour (QM 46-2). The machine was compact, with a straight sheet feed and a short paper path through the printing cylinder.

The two-colour machine had an unusual design: the two form cylinders could be shifted lengthwise relative to each other. They had a common offset cylinder, where two inks were combined simultaneously. The printing cylinder could also be shifted lengthwise and widthwise relative to the offset cylinder. In the pre-digital era, this provided good opportunities for placing the image in any part of the printed sheet.

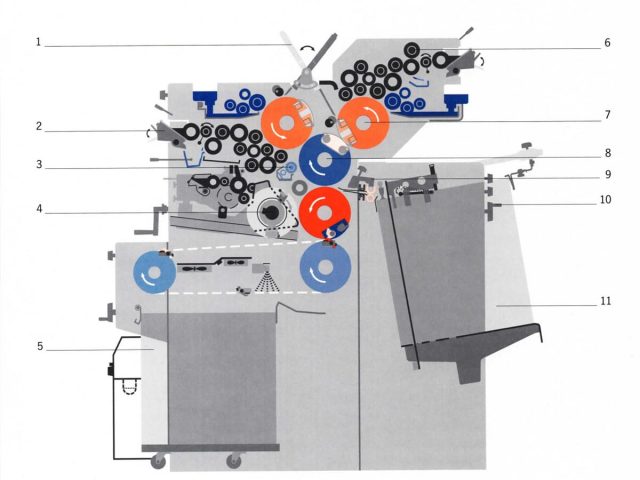

1 – Heidelberg Autoplate with integrated register system for both printing units

1 – Heidelberg Autoplate with integrated register system for both printing units

2 – Ink fountain with steel fountain roller. From 2000 – with laser-slit ink blades

3 – Automated blanket wash-up device

4 – Numbering, impressing and lengthwise perforation in one pass

5 – Smooth output to the delivery, with sensor-controlled pile lowering and fans

6 – Inking and dampening systems with roller wash-up system for the second printing unit (option)

7 – Easy registration system

8 – Bearer-on-bearer running and helical gears for long service life and lastingly top quality

9 – Electronic sheet travel monitoring

10 – Central sheet-size setting for feeder and delivery

11 – Pile table for fast loading of piles in all formats.

It’s easy to notice that Heidelberg dispensed with a huge number of unused options that had been developed for the T-Offset. Their development and production had required enormous amounts of money and effort, but practice had shown that most of them were unnecessary. The new machine was as versatile and automated as possible for any customer from day one.

Disadvantages of the Quickmaster QM 46

Despite its innovative approach, the Quickmaster 46 was an excellent addition to high-speed printing machines. It became a highly specialised machine for the commercial printing market. The design deliberately had a number of limitations that prevented it from replacing more expensive machines and prevented the Quickmaster from competing with them.Although the machine was designed for printing forms, business cards and other representative products, it still required time and paper for setup. An ordinary clerk could not print the number of copies he needed – the work still had to be done by specially trained personnel.

On a single offset plate, the inks had to be perfectly aligned, otherwise they would transfer from one ink unit to another and contaminate each other. The primitive push-type side stop did not ensure high-quality registration on the second pass of the sheet. It was impossible to print four-colour halftone work.

In addition, in the two-colour version, problems arose with ink registration when printing on thin materials at higher speeds.

Restyling

In 2000, the model was slightly modified. The designers finally got rid of the inconvenient screw-type ink fountain box of the printing machine. It was replaced by a lever mechanism, and the position of the ink zones could now be easily adjusted and even sketched on paper. The ink knife became more efficient and less prone to wear. Its surface was divided into zones by a laser.

In 2000, the model was slightly modified. The designers finally got rid of the inconvenient screw-type ink fountain box of the printing machine. It was replaced by a lever mechanism, and the position of the ink zones could now be easily adjusted and even sketched on paper. The ink knife became more efficient and less prone to wear. Its surface was divided into zones by a laser.

The second important improvement was the redesign of the wash-off device. In the first generations, the surface of the rubber wash roller was easily damaged by unsuitable chemicals. It swelled, and printers, knowing the cost of a new roller, refused to use it anymore.

Finally, quite a few parts on the self-loading and delivery mechanisms became metal. The old plastic gears quickly fell apart. Therefore, if you choose the Quickmaster 46, we recommend paying attention to the second generation, which has silver side covers instead of lilac ones.

Reasons for discontinuation

By the early 2000s, the market situation had changed dramatically. Budget digital copiers and printers, such as Xerox and Konica Minolta, entered the market, capable of printing full-colour runs with minimal preparation and cost. They offered speed, simplicity and low maintenance costs — exactly what the Quickmaster offset printer lacked. As a result, in 2005, Heidelberg officially discontinued the Quickmaster QM 46, focusing on the development of digital technologies in collaboration with Ricoh, as well as the promotion of more automated offset solutions in the mid-range and high-end segments.

The Quickmaster legacy

\Despite its short life cycle, the Quickmaster QM 46 played an important role in the transition period between classic offset and digital printing. It was an important attempt by Heidelberg to create a compact, versatile machine for short-run printing. The Quickmaster 46 found its niche in many print shops for printing simple products so as not to take up the expensive time of machines such as the Speedmaster with automatic plate changing.

Thus, the abandonment of T-Offset and the Quickmaster QM 46 put an end to Heidelberg’s attempt to introduce offset printing in banks and copy shops. They were replaced by toner devices capable of producing high-quality prints from a single copy. These machines were a logical step in the history of a company striving to meet the needs of a new generation of customers and technical processes in an era of rapid digitalisation.

Quickmaster QM 46‑2 Technical Specifications

| Parameter | Specification |

|---|---|

| Printing process | Sheetfed offset (1 or 2 colors) |

| Max sheet size | 460 × 340 mm (18.11 × 13.39 in) |

| Min sheet size | 140 × 89 mm (5.51 × 3.50 in) |

| Max print area | 453 × 330 mm (17.83 × 12.99 in) |

| Plate format | 505 × 340 mm; thickness 0.15–0.2 mm |

| Stock thickness | 0.04–0.30 mm |

| Feeder pile height | 490 mm |

| Delivery pile height | approx. 540 mm |

| Printing speed | Up to 10,000 sheets/hour |

| Inking system | 12–13 rollers (3 form rollers per unit) |

| Dampening system | Alcohol-free direct-film (DDS) |

| Gripper margin | 7 mm |

| Noise level | < 80 dB (DIN 45635) |

| Power requirement | ~3 kW (240 V, 1 Ph, 60 Hz, 16 A) |

| Dimensions (L×W×H) | 1,500 × 1,270 × 1,530 mm (59.1 × 50.0 × 60.2 in) |

| Weight | ≈ 1,030 kg (2,270 lb) |

| Production period | 1995 – 2005 |