11 of March, 2025 is a special day in the history of printing. Heidelberger Druckmaschinen AG is celebrating its 175th anniversary. For me, as the author of these lines, it is particularly significant that I have been close to the company for almost 7 per cent of its existence time.

In honour of such a wonderful event, let’s take a little look back at the history of the company and its famous products.

How the history of the company began

The history of printing technology has been marked by continuous innovation, beginning with Johannes Gutenberg’s invention of moveable type in the 15th century. His letterpress printing technique, which involved arranging individual letters, inking them, and pressing them onto paper, remained largely unchanged for centuries.

The industry saw a major breakthrough in 1810 when Friedrich Gottlob Koenig developed the first high-speed printing machine. Shortly afterward, steam engines were introduced, accelerating the evolution of printing technology.

This period of innovation attracted millers, who were not only refining grain processing but also working on better mechanical systems. Among them was Andreas Hamm, the son of a miller, who in 1850 took over a machine factory and bell foundry in Frankenthal. In 1856, he partnered with Andreas Albert, an experienced printing press expert, and together they manufactured high-speed presses alongside other metal castings. By 1864, their products were being shipped internationally.

By 1873, Hamm and Albert had parted ways, becoming competitors in printing press manufacturing. Hamm, determined to advance the technology, introduced a high-speed cylinder letterpress in 1875, which found buyers as far as Egypt. Following Hamm’s death in 1894, his son Carl Hamm sold the company, which was then relocated to Heidelberg and renamed Schnellpressenfabrik AG Heidelberg in 1905.

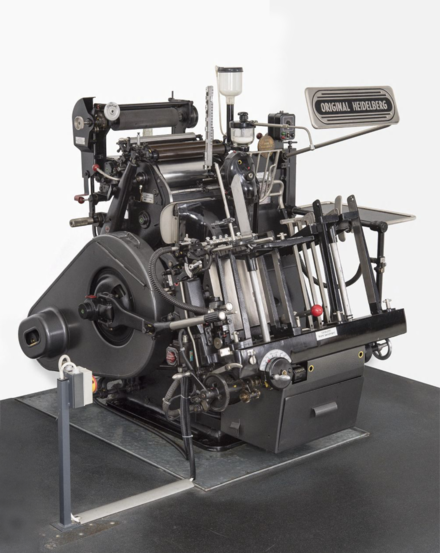

In the early 20th century, new advancements in printing technology emerged. Karl Georg Ferdinand Gilke, who arrived in Heidelberg in 1912, designed the “propeller-gripper,” a device that automated the feeding of paper into printing presses. This innovation significantly increased efficiency. After World War I, Heidelberg introduced the “Express,” an automatic platen press capable of printing 1,000 sheets per hour. This product gained rapid popularity, thanks in part to Hubert Sternberg, a key figure in the company’s management. Sternberg creatively marketed the machine by demonstrating it in a car-mounted format and allowing flexible payment options. His efforts helped solidify Heidelberg’s reputation. The production ramped up with assembly lines churning out 100 presses monthly.

In the early 20th century, new advancements in printing technology emerged. Karl Georg Ferdinand Gilke, who arrived in Heidelberg in 1912, designed the “propeller-gripper,” a device that automated the feeding of paper into printing presses. This innovation significantly increased efficiency. After World War I, Heidelberg introduced the “Express,” an automatic platen press capable of printing 1,000 sheets per hour. This product gained rapid popularity, thanks in part to Hubert Sternberg, a key figure in the company’s management. Sternberg creatively marketed the machine by demonstrating it in a car-mounted format and allowing flexible payment options. His efforts helped solidify Heidelberg’s reputation. The production ramped up with assembly lines churning out 100 presses monthly.

Mergers and expansions further strengthened Heidelberg’s capabilities. In 1929, the company combined forces with Maschinenfabrik Geislingen (M.A.G.), enhancing its manufacturing potential. The 1930s saw further technological breakthroughs, including a fully automatic high-speed cylinder press in 1934. The company’s international sales, which once accounted for 60% of revenue, were disrupted by World War II, leading to a temporary shift in production to precision lathes and hydraulic equipment. However, post-war operations resumed swiftly, and by 1957, Heidelberg had established the world’s largest printing press facility in Wiesloch.

Hubert Sternberg

Hubert Sternberg was the company’s CEO for more than half a century. Under his leadership, all the machines that set the standard for printing worldwide were developed.

There is very little information about him on the Internet, but this man can undoubtedly be called the father of printing. This is the man who founded the DRUPA exhibition, which every self-respecting printer still considers a must-see. I dedicated my article to this great man’s influence on 20th century printing.

How Hubert Sternberg turned a small dirty factory into a global industry leader

Of course, this person has his own story of ups and downs. For example, inspired by the success of letterpresses, he switched to offset presses later than others. But better late than never. This man’s contribution to the printing industry is enormous, and without him we would definitely be at a different stage of development.

An era of rapid development

The latter half of the 20th century brought new milestones. By 1959, about 100 thousand Heidelberg presses were in operation worldwide. The company entered the offset printing market in 1962, initially resisted by Sternberg but eventually embraced due to its advantages. Despite economic downturns in the 1970s, Heidelberg thrived as demand for color printing grew in the 1980s. A second factory was built in Amstetten in 1985, equipped with advanced computerized systems. Three years later, the company acquired the American web offset manufacturer – Harris, expanding into a new market segment.

The eighties were marked by the active introduction of electronics into the production of printing equipment. Heidelberg was not left behind – the first devices capable of monitoring print quality in spectrophotometric coordinates appeared on the market.

The GTO-DI printing machine was capable of imaging the plate in the machine itself without the need for an intermediate exposure unit.

Heidelberg GTO-DI (1990-1994) overview. Part 2. Computer-to-press technology appearance

The company first thought of creating a technology of rapid low-cost printing, which later grew into a whole direction – Quick Print Shop, whose baton today is carried by digital printing machines. The T-Offset series was the first attempt to create not just a stand-alone machine, but a whole range of equipment.

Heidelberg T-Offset overview: The forefather of digital duplicators

By the 1990s, Heidelberg was experiencing record sales, exceeding DM 760 million in the 1989/90 fiscal year. At DRUPA 95, the company introduced a new line of printing technology, enabling multi-color recto-verso printing with in-line coating and drying. The Quickmaster DI marked a shift to digital imaging, integrating laser technology for precision.

Under new leadership in 1995, Heidelberg pursued a transformation into a comprehensive systems provider, covering prepress, printing, and finishing solutions. The acquisition of Linotype-Hell, Stork Contiweb, and Sheridan Systems in 1996 expanded its capabilities. Joint ventures with CREO and Kodak followed, driving innovation in digital printing. Heidelberg also partnered with Microsoft for color control technology and collaborated with SAP for integrated media enterprise software.

The company’s financial achievements were solidified with its listing on the Frankfurt Stock Exchange in 1997, followed by inclusion in major European indices. Sales activities expanded, with direct marketing efforts reaching new regions, including Southeast Asia, Scandinavia, and Africa. In 1999, Heidelberg opened a state-of-the-art international spare parts center in Wiesloch to support its growing global operations.

Marking its 150th anniversary in 2000, Heidelberg inaugurated the Print Media Academy, a hub for industry knowledge-sharing. At DRUPA 2000, the company showcased innovations such as the Mainstream 80 rotary press and the Nexpress digital color press. Further acquisitions and strategic expansions reinforced Heidelberg’s status as a global leader in printing solutions, integrating finishing products and consumables into its portfolio.

Hugely unfortunately, the project PMA had to be scrapped. See how the Print Media Academy building looks today in our article.

By 1998/99, Heidelberg reported a high turnover of 7.7 billion DM (3.9 billion Euros), employing over 20 thousand people worldwide. The company strengthened its position in flexographic printing with a stake in Gallus Holding AG. It also expanded logistics operations, establishing the world’s largest graphics industry spare parts center in Wiesloch. In 1999, Bernhard Schreier took over as chairman, guiding the company into the digital era.

Heidelberg’s legacy of innovation and adaptability has positioned it as a dominant force in the printing industry, continuously evolving to meet the changing demands of the global market.

Read our other articles on the most famous printing machines of the past.

Surprisingly, the leading company in flatbed offset printing was the last of all manufacturers to come up with machines for this technology. The almost detective story of the development of the first offset machine is told in our article.

Heidelberg K-offset overview: first offset printing machine (1962-1986)

About Heidelberg’s most unsuccessful printing machine, which nevertheless laid the foundation for the development of high-speed printing.

Heidelberg Rotaspeed (1965-1976) overview. The most unsuccessful Heidelberg’s printing machine

About the world’s most common printing machine in the Guinness Book of World Records

About the unusual marketing that ensured that it wasn’t the customer who came to see the printing machine, but… the machine came directly to the customer for a demonstration.

The story doesn’t end there. We will continue to follow the history and development of the world leader in printing, which has been setting standards for the entire industry for 175 years.

We know much about Heidelberg presses. Our company can help you expertly choose a used printing machine, and not to make mistakes before buying.