Hello to all subscribers from LabelExpo India! If by chance you happen to be at this show in Delhi, I will be happy to meet you on the 15th of November at the TPH Orient booth.

I would like to share what I have seen in this wonderful, colourful and unusual country. We will talk more about Heidelberg and Manroland later, but today I would like to share the impression I got when I visited the booth of TPH ORIENT India.

Can you trust Indian quality?

You can read the history of the company without me on the company’s website. But I want to tell you about what I saw with my own eyes during my visit to the exhibition. The products of this company have quite a long history. It was founded by a newspaperman and Indian freedom fighter, Mr K.D. Kohli, and has undergone quite an evolution in its life, which I would like to tell you about.

One of the visitors, a flexo technologist with vast experience from one of the CIS countries, after seeing the machine said literally: ‘This is probably the best flexo machine at the whole exhibition’. I thought so too, and I will try to demonstrate why it is so.

One of the visitors, a flexo technologist with vast experience from one of the CIS countries, after seeing the machine said literally: ‘This is probably the best flexo machine at the whole exhibition’. I thought so too, and I will try to demonstrate why it is so.

For many printers who have worked with German, Italian, British-made printing equipment, the word ‘Indian equipment’ evokes a wry chuckle. Sheet offset printers will remember licensed Dominants, web printers – machines Zirkon and RO-62 under licence from LBW Polygraph from GDR. But I want to assure you that this time is long over. Today Indian machines are not inferior to the best world models neither in price, nor in quality, nor in components.

The most famous products of TPH Orient are, of course, newspaper printing machines. If even your print shop did not have such a newspaper machine, you must have met them at exhibitions – from DRUPA to PolygraphInter. In the last 15 years, however, newspaper production has noticeably declined. The company has not lost its potential at all, on the contrary, it has managed to adapt perfectly to the changed conditions.

Today the production is based on digital narrow web machines and flexo lines. For assembly production mainly components of European companies with branches in India are used.

X-PRESS flexo printing machine

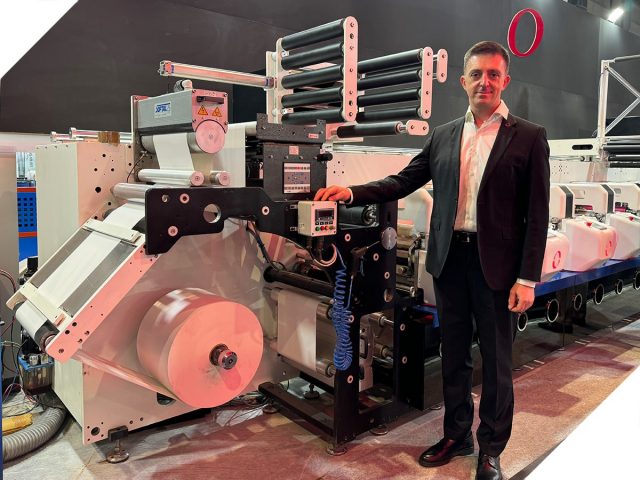

Let us walk the length of the flexo machine installed at the exhibition and try to pay attention to its features.

What immediately catches the eye is the impressive design with a red illuminated oval that contrasts with the dark blue and black colour scheme. The machine is without a doubt eye-catching and even mesmerising. I can say that the design is more oriented more towards European taste rather than Asian taste. The firm is constantly working on the design, so if you decide to order this machine, perhaps it will look even more interesting.

Overall impression

The machine is not simple and not primitive at all. It is based on the most modern servo drive. This reduces vibration, improves print quality by eliminating the run-out of gears. It is a pity that I forgot my vibrometer at home, which we use for equipment inspections. But even without it it is noticeable that the machine is quiet and stable at 200 metres per minute.

Please note that all components are assembled using European components, which are available locally. The systems responsible for web tension control, for coronary sensing of the material, for dust removal and for register control are made by the German company Erhardt+Leimer (EL).

Print unit

You can see for yourself how convenient it is to access the print unit. Ink can be added without stopping the machine from the left side of the machine. By opening the lid from above, the platemaking cylinder is accessible. Both conventional photopolymer moulds and sleeves can be used. The diameters of the cylinders can of course also be used.

You can see for yourself how convenient it is to access the print unit. Ink can be added without stopping the machine from the left side of the machine. By opening the lid from above, the platemaking cylinder is accessible. Both conventional photopolymer moulds and sleeves can be used. The diameters of the cylinders can of course also be used.

Longitudinal registering is carried out automatically by shifting the pinion along the paper web movement. Transverse register shifts the two cylinders in a horizontal plane.

Proprietary print unit. Orient’s patented X-gear design and gearbox integration system results in a Pitch Circle Diameter (PCD) of only 2 microns, resulting in a significantly faster machine, minimal noise at high speed, excellent register and higher print quality.

After the ink has been applied, UV drying comes into play. In this case, water-cooled GEW modules with 160 W/cm lamp power are installed. A refrigerator is installed behind the machine.

Peripherals

Above the machine is a mobile delamination-laminating system, a web turner, two units of rotary punching and a de-skimming unit.

Note the register control system. It is specially displayed on a huge monitor. The control module is manufactured by Erhardt+Leimer (EL).

Almost any equipment can be ordered as an option. Literally I was discussing the configuration of machines for convex braille.

So, why is this machine worth buying?

1. The company doesn’t skimp on the little things. If there is a 50 euro difference in the cost of a component, there is no point in compromising quality.

2- Higher quality purchased metal than most manufacturers. The steel casting suppliers are still the same as thirty years ago, from the days of coil machines.

3. Patented gear design. High PCD accuracy down to 2 µm, resulting in stable printing and quiet machine operation.

4. Possibility to use both photopolymer moulds and sleeves.

5. The most important thing – quick reaction in case of need of customer support.

If you choose a new flexo machine capable of printing stably at high speed, but at the same time for reasonable money, pay attention to this series.

The machines are supplied by BBS Trading. Here’s a link to their website.

Download the brochure for this machine here

And if you are choosing used equipment but would like to check its condition before paying the supplier, choose PressInspection’s services.

See you next time soon!