Test Karo

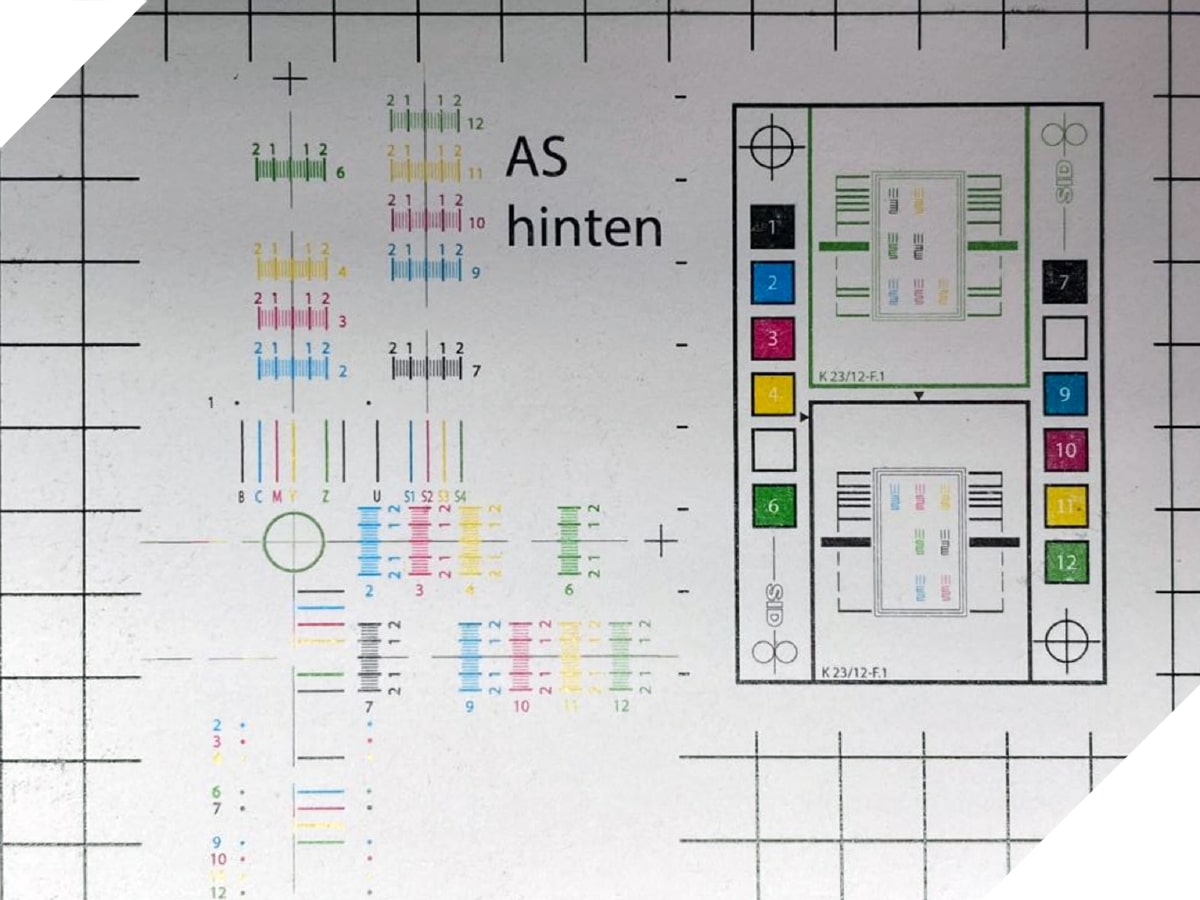

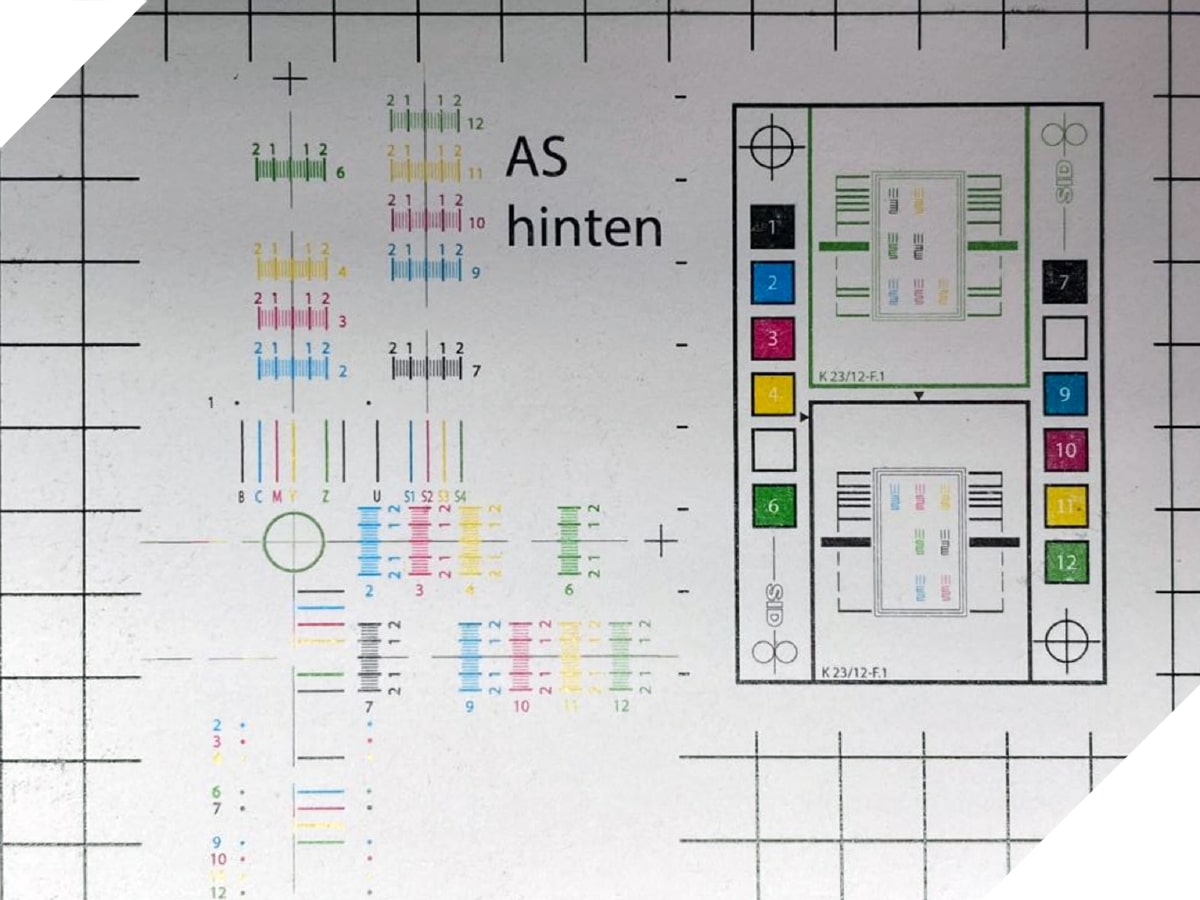

A fairly complex test for checking the sheetfed system of a sheetfed machine. It consists of a grid with specially applied elements to check the colour matching when printing in both straight and perfecting mode. This test is especially important when selecting a printing machine for high-responsibility works with high accuracy of colour matching.

The task of the test is to determine the condition of the sheet transfer system as a whole and between individual units. With the help of decoding of this test the general condition of the sheet transfer system at all - grippers, perfecting device.

Align the lateral register using only the center element at the top part of the sheet. Combine all colors marked with numbers to the base black that is not marked with a number. Do not check or attempt to align the lateral register using other elements!

The next step is to align the circumferential register using only the two elements on the right and left at the top of the sheet. All colors that have numbers are also aligned to the black mark. Do not check or attempt to align the circumferential register using other elements!

The results are then evaluated for possible deviations in the sheet transfer, focusing on all 9 elements. The presence or absence of “trapezium”, “bow”, doubling and other defects is checked, both in the individual units and as a whole. All control sheets are put aside and labeled. Photos are taken of each element, identifying its location on the sheet.

Important.

The file must not be screened. Only individual plates are made!

2. The test speed is between 70 and 85% of the maximum press speed.

3. If the press has a perfector, it must be set to a straight mode.

4. The goal of the test is NOT to achieve optimum register over the entire sheet!

Tension For Different Models

|

Printing Press Manufacturer And Model |

Total thickness = calibraied sheets + blanket, mm |

Blanket Tension, Nm |

|

MAN Roland 200/ 300/ 500 |

2,30 |

40-45 |

|

MAN Roland 700 |

3,25 |

50-55 |

|

MAN Roland 800/ 900 |

3,25 |

65-70 |

|

Heidelberg SM102/ CD102 |

3,25 |

65 |

|

Heidelberg XL105/ XL106 |

3,25 |

65 |

|

Heidelberg SM72/ SM74/ SX74 |

3,25 |

40-45 |

|

Heidelberg CD74/ XL75 |

3,25 |

40-45 |

|

Heidelberg GTO46/ GTO52 |

3,25 |

30-35 |

|

Heidelberg SM52/ SX52 |

3,25 |

30-35 |

|

KBA Rapida 74 |

3,20 |

40-45 |

|

KBA Rapida 105/ Rapida 106 |

3,20 |

60-65 |

Test duration: 3-5 hours

Paper quantity: required number of sheets — 100-150 per printing section, 130-150 g/m2.

Requirements: new blankets and pads installed.

Web tension checked with a torque wrench.

Ink and colour order:

B-C-M-Y. If there are more than 4 colour sections, inks other than triad inks must be used for the rest. If this is not possible, M can be alternated with C.

Printing is performed on plates made according to a special file provided by us. The file is suitable for testing machines equipped with up to 12 separate printing sections. For testing, the number of plates is determined starting with form 1 (black), in accordance with the number of printing sections.

Why the Karo print test is so important?

The machine manufacturer allows for a tolerance of 0.1 mm for image deviation in perfecting mode, which is unacceptable for printing in straight mode (where 0.05 mm is critical). The same bar is responsible for operation in both modes. If the perfectingl device is activating from time to time and the machine is already quite worn, we will see a deviation of up to 0.1 mm even in direct mode.

If you only work in perfecting mode, this will not be critical, and you may not notice the difference. But if it is a long machine that will be used in both single-sided and duplex modes, for example, for printing packaging, securities or lenticulars, this deviation may be important and will affect the quality of the product.

In addition, if we detect a discrepancy on the Karo print test, we must immediately pay attention to the air settings. Often, the compressor may not be working properly, and we need to find out what is causing the sheet to ‘throw’.

And if we see a discrepancy of more than 0.1 mm when working with sheet reversal, this only means that the machine requires serious investment.

Kiss-Print Test

Karo Print Test