Cardboard Puzzles And Toys

Baseline situation

Polish company decided to launch a collection of puzzles – both traditional and 3D. The problem – they need to develop several products and launch sales on Amazon and Etsy.

The most important requirement for puzzles is that they should be interesting for the consumer, well-made and unique. However, even the first communication with three local printing companies showed that they were ready to take on the production of typical orders. But there were no such people willing to bother with technology development or devote their time to new customer products. So we decided to develop the products and technology ourselves.

Project Objectives

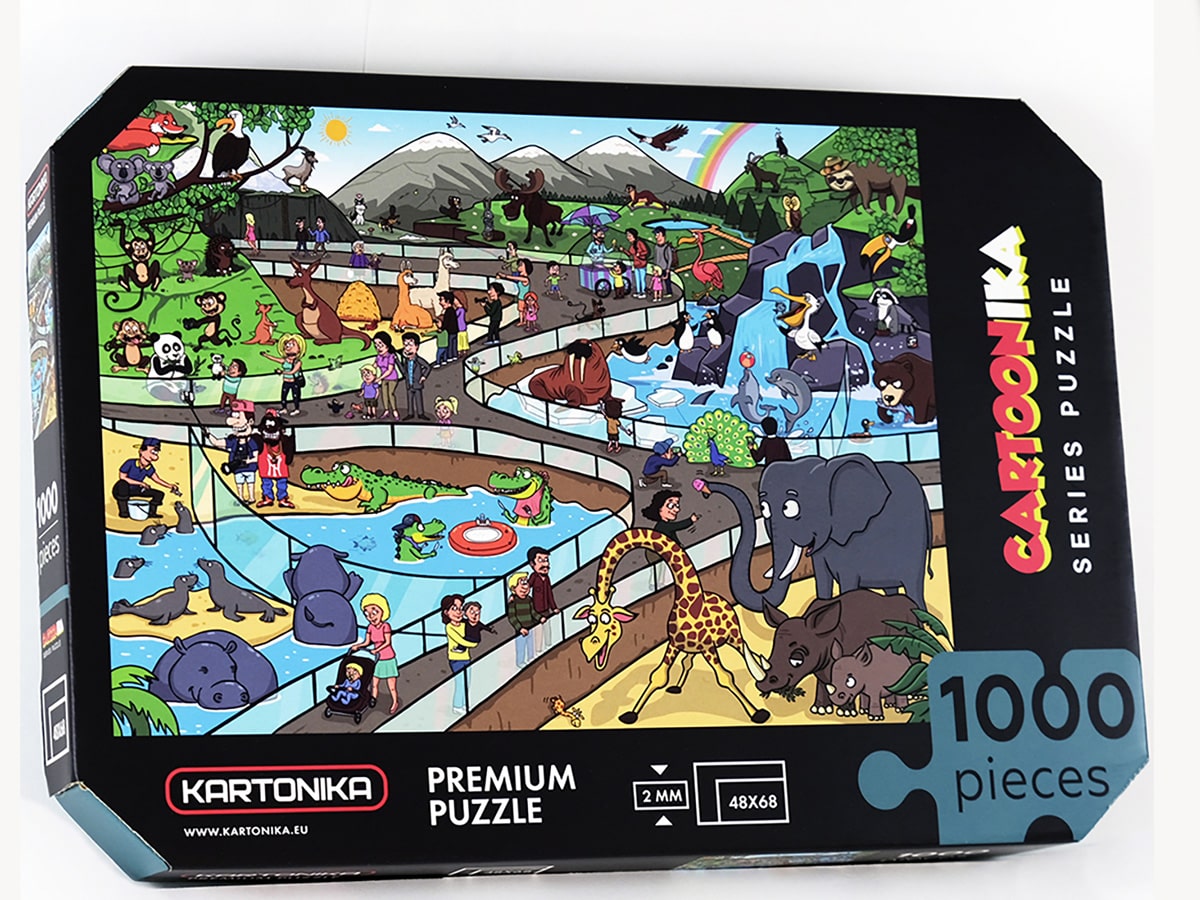

Several directions were chosen for the development of the project. The first direction is premium level puzzles printed on blue waterproof cardboard with a thickness of 1.9 mm, in original packaging and with drawn plots.

The second direction is 3D puzzles made of micro corrugated cardboard, which are various figures glued together and which become a fun art object on the table. Among them were various animal heads, but the most popular was a cardboard human skull.

The task was to produce industrial batches of these products using conventional printing equipment.

Each of our experts has training certificates from the Print Media Academy of Heidelberg Druckmaschinen, the company we have been working for for many years. So we can confidently say that we can take apart any Heidelberg printing machine, strip it down to its screws and tell you what each one is for.

We are available to help you with your printing technology needs or to advise you on the selection of a new or used machine. We have run technologies such as IML, lenticular printing, embossing on SM74 at various companies, so I would be delighted if my knowledge and experience could be of use to you. Just write and we will find a way to make you better than your competitors.

Step 1.

At a preliminary conversation with the customer several directions were defined: we produce classic jigsaw puzzles for sale and 3D models made of corrugated cardboard for self-assembly by the buyer.

Legislation research has shown that according to European legislation, jigsaw puzzles with more than 500 elements are not considered toys, and they are not subject to the rules of goods for children. In addition, additional taxes on packaging manufacturers apply in different countries (e.g. Germany), where it is necessary to register “packaging filled with goods” with the ZSVR. The tax is called “VerpackG” and applies to any packaging manufacturer.

The next step was to find a manufacturer who could produce the required goods. A small company in Lithuania was found that produces puzzles of the highest quality by hand.

The puzzle production technology is not shared among printers so as not to create competition. It needs a special equipment. For example, it should take 400 tonnes pressure to cut a thick B3 sheet. In addition, it is necessary to make sure that the cut small elements do not disintegrate into hundreds of small parts inside the machine. This is why the Bobst Autoplatine is not suitable for puzzle technology. The Chinese presses available in Poland can produce puzzles up to 1,7 mm, while our product was supposed to be at a premium level.

The photo does a good job of demonstrating what a quality premium puzzle piece should look like.

Together with the printing company, we developed a technology for die-cutting and producing puzzles up to 2 mm thick. This process took almost half a year.

Step 2: Competitor assessment.

Of the competitors on the Polish market, there are several large factories orientated towards cheap jigsaw puzzles – Trefl, Castorland and some others. They sell their old collections at very low prices, often below the cost of production. Therefore, in addition to technology, the pattern and quality of execution will matter.

In addition, the shops widely present the products of factories Educa (Spain), Ravensburger (Germany) and Clementoni (Italy), which do not need to be presented to puzzle lovers. In order to compete with them, the products must be better in quality and have their own individual advantages that are clear to the customer.

We have also analysed what is being sold on the marketplace through Amazon. Several vendors claimed high quality, but the items were made of laminated cardboard, which tends to delaminate quickly. This can be seen in the photos. This quality is unacceptable.

Etsy, Amazon, Shopify, Allegro, as well as wholesale partners with whom the customer had agreements were identified as sales channels. It should be noted that the bet on Allegro was wrong, they managed to sell only a few pieces during the whole time. But Amazon was more suitable for such a product than any other.

Step 3.

In parallel, our packaging department developed an attractive packaging that could replace the classic “rigid-box” and was twice as cheap to produce. In terms of attractiveness, it immediately caught the eye due to its non-standard shape.

The jigsaw puzzles box were tested for attractiveness and production quality and a batch of 250 pieces of each of the 8 items was produced to test the saleability.

We decided to create for the client a simple WordPress website with WooCommerce module and connection to PayU payment system, so that the client could make transactions directly from his website. We registered the client’s company in GS1 and received a 13-digit barcode for each SKU.

Step 4.

We opened an account on Amazon SellerCentral. The trade mark was registered (waiting for the documents took 4 months according to FastTrack procedure). Nevertheless, we decided not to wait for the registration of the product and processed the product in the cards as unbranded (Amazon allows you to do this by using the Generic keyword instead of the brand name). We made product cards, took photos and worked out the description of the product.

Step 5: Conclusions.

In the first month the advertising costs amounted to about 30% of the cost of the product. With the cost of the product at 19.99 euros, the costs were:

VAT – 20-21% depending on the country (about 4 euros),

FBA costs – about 5.8 euros.

Advertising costs – about 30% of the cost of the product – €6 (one out of eight people who viewed the product made a purchase decision). This shows that the card and keywords should be worked on.

Three positions out of eight were not the most popular. But two of the eight items were so interesting that the batch was sold out within three months.

Future plans

After five months, the customer decided to reformat the business and look for more expensive products to sell, as the advertising costs are high and the selling price of the product is quite low.

The resources available to the customer cannot cope with the production and accounting of the product. The company is now concentrating on printing customised puzzles for individual customers.

To summarise, it must be said that during the launch of any startup, the customer will inevitably encounter many difficulties which, at the beginning of the journey, he cannot even imagine. Our task is to help them get through the process as painlessly and quickly as possible. But at the end, by trial and error, he is bound to find his place.

- Note 1. On our website we respect the principles of confidentiality. We are keenly interested in the development of our clients, who would not be very happy with the emergence of competitors who want to repeat their experience.

- Note 2. The point of the case study is for our potential customers to familiarise themselves with our company’s experience. Blind copying of the case study will not lead to a positive result, as each business, as well as location, is purely individual.