Project development and start-up of a large printing house

Baseline situation

The project was developed over two years. A global market analysis of the region was carried out and it was found that all label and packaging producers worked with standard oil-based inks. At the time the project was launched, there were no machines in the market in the region equipped with UV lamps, which would ensure fast ink drying and transition to post-printing. In addition, UV inks would allow for brighter images and high speeds on non-absorbent materials, including lenticular plastic.

Project Objectives

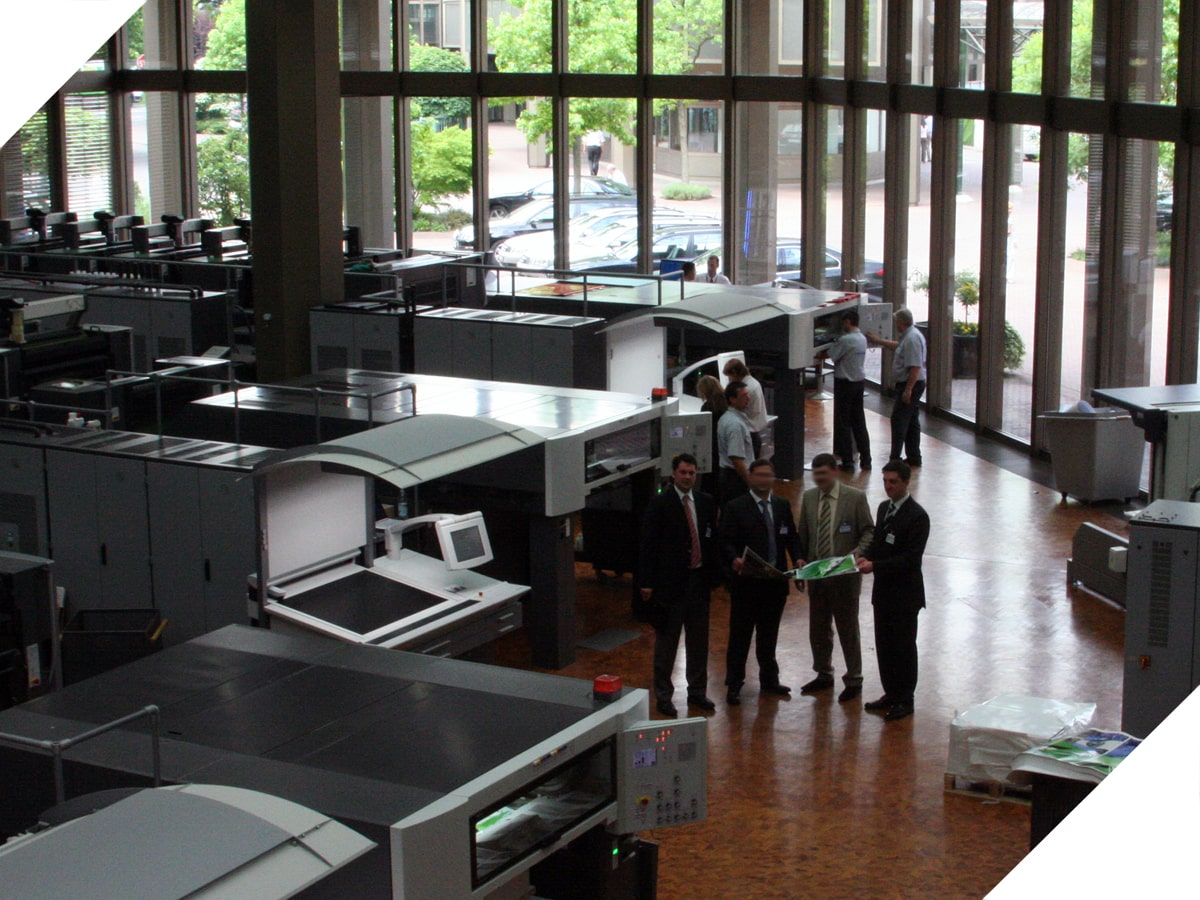

Work with the founder began with the need to convince him that a more expensive option at the initial price would pay for itself faster than a set of equipment that was already on the market at many competing printers. A VIP tour was organised for the representative of the owner of the company to Germany to the manufacturing plant – Heidelberger Druckmaschinen AG. Due to the importance of the project, a meeting with the general director of the manufacturer took place during the trip. The project involved the purchase of equipment worth several million euros over a period of three years.

Each of our experts has training certificates from the Print Media Academy of Heidelberg Druckmaschinen, the company we have been working for for many years. So we can confidently say that we can take apart any Heidelberg printing machine, strip it down to its screws and tell you what each one is for.

We are available to help you with your printing technology needs or to advise you on the selection of a new or used machine. We have run technologies such as IML, lenticular printing, embossing on SM74 at various companies, so I would be delighted if my knowledge and experience could be of use to you. Just write and we will find a way to make you better than your competitors.

Business Plan

The equipment complex and its business model were discussed taking into account the market requirements. At the time of the company’s launch, there were no other companies in the region using ultraviolet colour fixation technology. It was supposed to be the main competitive advantage of the enterprise.

Taking into account the fact that there are many perfumery enterprises in the region, it was planned to bet on the production of packaging made of plastic, as well as lenticular images. However, when everything was ready for launch, the financial crisis hit and it became risky to purchase equipment for the unique technology. It was decided to turn to conventional printing technology with IR dryers, but to order printing equipment with optional equipment, which none of the competitors had.

The economics of production and the standard hour of work of the printing house were recalculated. Detailed plans for the location of each piece of equipment were provided. With our help, a company director was selected to take over the day-to-day work of drawing up the shop floor plan, recruiting staff and developing the process chain.

Premises

At the same time as the project was being developed, work was underway to find premises for production. In total, about 15 options were considered. But some of them were not suitable, and other premises were to be demolished within the next five years.

Dismantling and relocating the complex would cost around 100 thousand euros, so the bet was placed on finding premises that would allow for development for at least 10 years.

Financial Crisis

After the project was submitted to the founder for approval, the economic crisis hit and funding was cut.

The money had already been invested in production, so the project had to be urgently redesigned for the purchase of second-hand equipment, postponing the purchase of equipment with UV ink-setting technology to the second stage.

Instead of three printing machines, only one was purchased, and much of the auxiliary equipment was replaced with used rather than new.

Nevertheless, production was started and very soon reached its design capacity.

After the launch, the company moved to the second stage – implementation of CRM-system for printing production. The launch took about 9 months.

Two years after the launch, at the end of the financial crisis, the project was redesigned again, and new investments allowed the company to go straight to the construction of its own building for specific printing machines. Today, the company is the undisputed leader in its field and the only player on the local market with UV drying machines.

The experience of this case shows the need to take into account rapidly changing market circumstances, and to react quickly to them.

- Note 1. On our website we respect the principles of confidentiality. We are keenly interested in the development of our clients, who would not be very happy with the emergence of competitors who want to repeat their experience.

- Note 2. The point of the case study is for our potential customers to familiarise themselves with our company’s experience. Blind copying of the case study will not lead to a positive result, as each business, as well as location, is purely individual.