In the early 1990s, the printing industry faced a major transformation. Print runs became shorter, deadlines became tighter, and quality standards began to tighten. It became clear that the industry could no longer rely on the same work processes as in the 1980s — with analogue plates and numerous manual steps to prepare intermediate images using photographic film. Printing houses needed a compact but professional, highly automated printing machine for formats up to A3+, capable of performing tasks previously intended for B2 format machines.

Reasons for the emergence of a new printing machine

Throughout its last hundred years, Heidelberger Druskmaschinen AG has always tried to predict the direction of printing technology. Needless to say, it entered the 1990s with a rather diverse range of equipment.

The B2 format was represented by overlapping series: K-offset, S-offset, M-offset, and even SM72. However, for the rapidly developing A3 market, only the GTO, which was already becoming obsolete, was available. The simple T-Offset series covered the simplest jobs. But what was the point of its excessively bloated range of optional equipment? Just look at how many automatic feeders and delivery units were provided. But each of these options had to be sold.

The author of these lines remembers well his first trip to Heidelberg in 1998. And in the warehouse in Wiesloch, all these devices that had not found a buyer were still gathering dust on the shelves…One potential solution was to build a computer-to-press sheetfed offset machine based on the GTO 52 platform. However, that concept proved prohibitively expensive and required special printing plates. It quickly became obvious this was a niche product—not suitable for widespread adoption.

Another issue emerged: the GTO 52 platform, despite its strengths, lacked the architecture to support deeper automation. The cascade feeder could push the machine to 12 thousand sheets per hour, but there was no space for Autoplate, wash-up devices, or even remote control systems. A new, faster and more universal press was needed.

The answer came in 1994 with the launch of the Heidelberg Speedmaster SM 52. It was the first 36×52 cm format press with automation features on par with Heidelberg’s larger SM 74 and SM 102 models. It carved out a niche between basic models like the GTO 52 and full-size B2 presses — targeting professional short- and medium-run printing.

By 1995, the GTO line had reached its functional limits. No more automation features such as CPC were added. The cascade feeder was abandoned in favor of a speed cap at 8 thousand sheets/hour. All high-speed options were now reserved exclusively for the SM 52.

Now, over 30 years later, the SM 52 remains impressive in terms of automation and production capabilities.

Design and Operating Principles

The SM 52 utilized a central drive geartrain with helical teeth, just like the larger Speedmaster presses. This ensured smooth sheet transfer and high registration accuracy, even at speeds up to 15,000 sheets/hour.

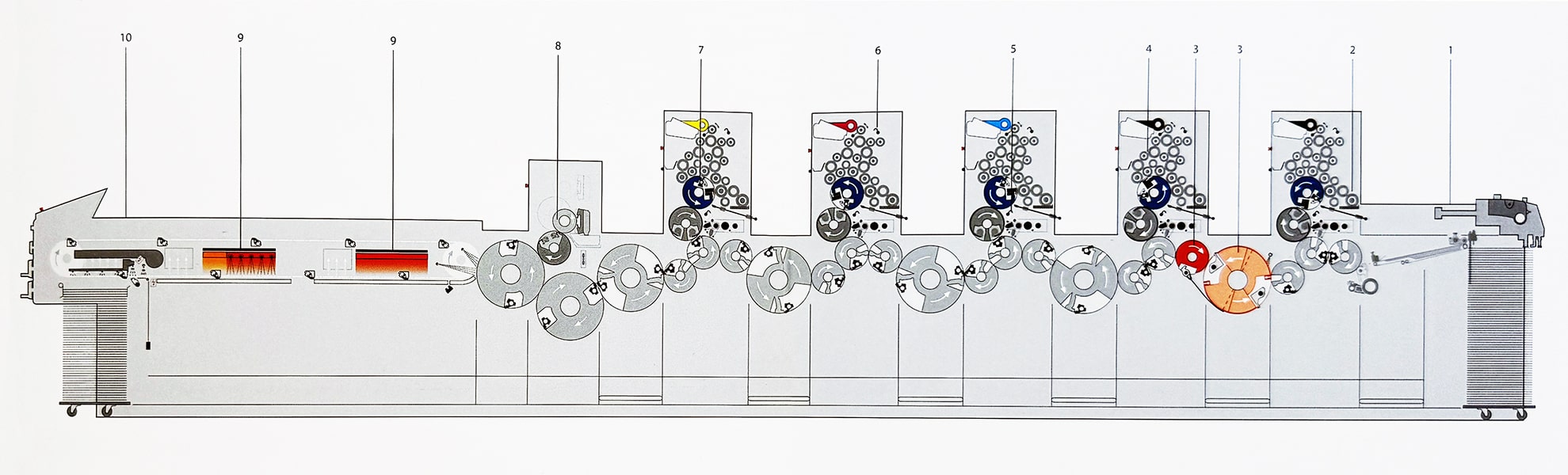

1 – Feeder with vacuum belt and switchable from cascade to single-sheet mode, 2 – Alcolor dampening system, including Vario function, 3 – fully automatic sheet perfecting device, 4 – short ink unit mode, 5 – offset and printing cylinder wash-off devices, 6 – ink roller wash-off device, 7 – Autoplate automatic plate changing device, 8 – Coating unit with two-coating or chamber coating system, 9 – DryStar Combination dryer in extended delivery, 10 – high-pile delivery with Venturi nozzles

Its sheet feeder offered excellent precision, even with thin or coated stocks. Unlike the GTO 52, the SM 52 used a vacuum tape feed table. The feeder could run in both cascade and single-sheet modes — particularly useful when handling thick postcard stocks.

The inking unit was conventional: four form rollers and a sophisticated ink duct. CPC-controlled presses came with automatic ink zone adjustment. One- and two-color models often had manual ink key control, but even these featured laser-cut segmented ink knives and lever adjustments for easier calibration.

All SM 52 presses came standard with CPTronic, Heidelberg’s digital control system, allowing the operator to monitor and adjust machine parameters in real time. As early as 1995, the SM 52 was ready for the emerging CIP3/CIP4 standards — years ahead of many competitors.

Depending on the generation, the printing machines differed in colour. The first machines from 1995 to 2000 were painted in a classic dark grey. One of our customers at the time told me that he was buying Heidelberg because of their practical colour. However, in 2000, the side panels became silver. Due to the habit of leaning the printing plates against the sides of the printing machine, the SM52’s attractive design very quickly became a disadvantage. They even had to be repainted. In 2008, the panels were redesigned again and became convex.

Model Configurations

The Heidelberg Speedmaster SM 52 became the most automated press in its class. Even by today’s standards, its feature list remains competitive.

Every machine was equipped with Autoplate automatic plate loading. Each printing unit had a dedicated wash-up system with separate solvent and water spray nozzles, plus a programmable wash cloth rotation system. The press allowed full control of wash sequence, volume, and solvent mix from the CPTronic console.

CPTronic allowed operators to predefine material thickness, speed, and dampening parameters—saving time on every makeready. These features wouldn’t become common among competitors until after 2000.

Operators could enter sheet length, width, and thickness into the control panel, and the press would configure itself in seconds.

The base model, SM 52-1, was a one-color press used for forms, tickets, and mono jobs. Two- and four-color versions followed, with the SM 52-4 becoming the most popular configuration for brochures, flyers, and catalogs.

In 1996, Heidelberg introduced the five-color SM 52-5+L with inline coating—making it the first B3 press capable of applying varnish in a single pass. In 2000, a six-color version (SM 52-6+L) was launched, ideal for premium packaging and commercial print.

There were two types of coating units offered:

-

Roller-type coating: Ideal for frequent job changes and quick varnish adjustments.

-

Chambered doctor blade system with anilox rollers: Preferred for repeat jobs requiring consistent, stable coating volumes.

Heidelberg also offered eight-color perfector models (SM 52-8P).

Special Features

Some machines with short delivery stacks were fitted with numbering and perforation units, commonly used for security documents, tickets, and business forms.

Customers could choose between standard and extended delivery configurations. Short delivery was simpler and less expensive, but limited the press’s ability to handle heavy stocks and long runs.

Varnishing units could be equipped with IR dryers and recirculation systems—especially useful when printing on coated paper or carton board.

The Printmaster PM 52 Division

The SM 52 gained widespread recognition after its release. However, its high price attracted cheaper imitators. These alternative machines sometimes won public tenders simply because their technical specifications looked similar on paper, even if their actual capabilities were incomparable.

Here is an example of one such manipulation: Heidelberg’s integrated towel-based cleaning system required the development of a tension-adjustable winding mechanism (a dry roll of fabric costs around €5), a fluid supply system and programmable logic for setting cleaning cycles. The system was more expensive to manufacture but much cheaper to operate. Some competitors simply offered pre-moistened fabrics (€20 per roll) and called it ‘the same washing function’, receiving the same evaluation in the tender.

In addition, some customers did not need a high-speed machine and did not want to pay for features they would never use. But, as we know, the GTO 52 could no longer meet modern requirements, and Japanese alternatives gained market share.

To capture the mid-range segment, Heidelberg launched a new line in 2003 – the Printmaster PM 52. These simplified versions of the SM 52 had slightly less automation but lower prices, targeting entry-level print shops.

However, this caused confusion. The PM 52 looked like an SM 52 but lacked many of its key features: manual plate loading Easyplate instead of Autoplate, no CIP3 interface, basic dampening controls, and simplified wash-up systems.

In 2008, Heidelberg discontinued the PM brand and consolidated all models under the Speedmaster SM 52 name again — regardless of their configuration or delivery height.

Ongoing Innovations

In 2006, a new configuration with a separable colour unit was introduced, allowing some of the rollers to be switched off. Only 12 of the 16 rollers could work with small text jobs.

In response to requests from users who printed on thick cardboard, Heidelberg introduced segment-controlled cylinders at DRUPA 2008. The transfer cylinders had a variable diameter due to their division into several segments. The new solution made it possible to handle cardboard up to 0.6 mm thick.

As mentioned earlier, the Heidelberg Anicolor system was also born from the SM 52 platform. It virtually eliminated makeready waste and helped redefine short-run offset printing.

Rebranding as SX 52

In 2012, Heidelberg rebranded the SM 52 as the Speedmaster SX 52, aligning with a broader corporate strategy. No major mechanical changes were introduced; the updates were primarily electronic.

The SX 52 featured a refreshed design, new control interface, and cloud-based integration via Prinect. Mechanically, it remained compatible with the SM 52—making both series easy to service as one family.

SX 52 versions were available with coating units, and some included Anicolor systems.

Decline in Demand

By the early 2010s, demand for 52 cm offset presses declined. Digital presses were rising fast. At the same time, no major offset “revolution” occurred. The Anicolor system catered to a narrow segment, while personalized digital presses largely overtook the Quickmaster DI’s market.

Commercial print jobs continued shifting to digital, especially in short-run advertising. Heidelberg also pivoted to digital solutions, and legacy models began to phase out.

The Quickmaster 46-4 DI ceased production in 2006 when Heidelberg completed its ‘Computer-to-Print’ strategy.

One- and two-color QM 46 models were phased out in late 2005.

There’s been no formal announcement on ending the SM 52/SX 52 series, though Heidelberg’s website no longer lists them. Nonetheless, used SM 52s remain in active demand worldwide.

Current Use and Market

Today, used SM 52 and SX 52 presses are still in high demand in Eastern Europe, Asia, the Middle East, and Latin America. They’re well-suited for printing brochures, forms, packaging, hang tags, apparel labels, mini catalogs, and business cards.

They remain popular thanks to their reliability, print quality, and ease of maintenance.

With spare parts still available and many trained technicians on the market, the SM 52 remains a wise investment for printers who wish to stay in the offset sector.

Conclusion

The Heidelberg Speedmaster SM 52 was truly ahead of its time. Decades after its debut, it remains relevant for those who know how to get the best out of offset. In an era of supply chain constraints and rising B2 costs, the SM 52 stands as a true workhorse of modern print production.